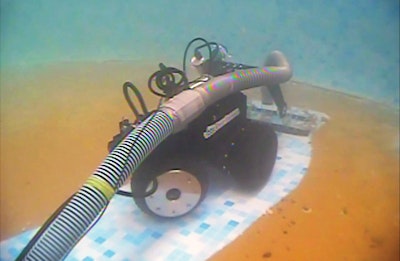

The Deep Trekker submersible drone camera, shown here in a water tower, can “fly” through water via remote-controlled thrusters and dive as deep as 500 feet.

Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

Inspection + Get AlertsAbout four years ago, the operator of a cogeneration plant in a medical center in Houston wanted to inspect the epoxy paint inside a massive 9 million-gallon, chilled-water storage tank. Only one problem: The logistics of moving the required equipment to the top of the tower, coupled with using a scuba diver at that depth, posed cost and liability concerns.

But OLC Services, which inspects and cleans tanks and vessels — primarily HVAC cooling towers at commercial buildings and similar systems at industrial plants — provided a solution: a DTG2 submersible inspection camera made by Deep Trekker. (The DTG2 has since been replaced with a next-generation version called the DTG3).

“We went in with a control tether line and took the camera straight down to the bottom of the tank,” says Shelby Howell, vice president of operations and engineering at OLC, a division of Houston-based SWS of Texas Inc.

“Then we guided it along the bottom and used a sample grabber to collect some of the sediment at the bottom, then came right up. The whole operation took only about an hour. This unit is one of the most remarkable and versatile remote-operated vehicles I’ve ever run across.”

That particular job didn’t require draining the cooling tank, which underscores why OLC (which stands for “online cleaning”) owns three Deep Trekker cameras. Two are three-wheel crawler cameras: a DT640 with rubber wheels and a DT640 with magnetic wheels that enable it to climb metal walls in tanks, ships and the like. The third is the aforementioned DTG2, which can “fly” through water via remote-controlled thrusters and dive as deep as 500 feet, he says.

“It’s the most innovative underwater-inspection vehicle I’ve ever seen,” he says.

No confined-space entry

Established in 2015, OLC — which primarily serves customers in Texas — has invested nearly $55,000 in the three machines. The battery-powered machines allow the company to serve a variety of customers.

As an example, Howell cites fire water tanks commonly found in plants and commercial businesses. The tanks require periodic inspections to determine if there’s corrosion, too much sediment buildup and so forth.

The Deep Trekker cameras offer two competitive advantages: They virtually eliminate the need for confined-space entry, and they can perform inspections without draining water from tanks or vessels and refilling them — two time-consuming and expensive processes, he notes.

“We can do an inspection in 30 to 40 minutes, which is much faster than if a tank had to be drained. Draining a large cooling tank could take four to eight hours and a small one might take two to three hours — and then there’s refilling time, too.”

Another advantage: No need for confined-space entry by divers.

“These machines provide us with a very efficient process that greatly simplified the logistics of inspecting a tank filled with water,” Howell adds. “It’s very economical to drop these cameras into tanks and it doesn’t disrupt the owner’s operations, either. That’s huge because most of them can’t shut down without causing major financial issues.”

Conserving water

In addition, eliminating the need to drain tanks saves water — no small issue in an area where water is a scarce resource and costs anywhere from $10 to $13 per 1,000 gallons.

“We don’t want to waste a valuable resource,” Howell says. “And we don’t want to tie up their personnel, and they don’t run the risks associated with confined-space entry.”

Furthermore, the machines help OLC generate business by making tank inspections faster and easier — and less risky.

“The costs of these camera inspections are relatively low, which makes our service competitive and attractive to customers,” he says. “So they help us make more money.”

The cameras are very versatile, too. The DTG2 also can retrieve small items with an optional, pincer-style “grabber-arm.” And along with performing inspections, the DT640 — which can operate at depths down to 164 feet — comes with a dual-intake vacuum-head kit that sucks up debris from tanks via a hose and a vacuum pump, Howell explains.

Versatile moneymakers

As an example of the machines’ versatility, Howell points to water-towers inspections, which often reveal debris that must be removed to meet potable water standards. An OLC employee can carry the lightweight DT640 in a backpack up to the top of a tower, lower it into the tower for an inspection and then guide it as it sucks up tank sediment and other debris, he explains.

The machine also can be equipped with optional attachments that perform functions like pressure washing, bulldozing and more.

“We’ve even used the DT640 to inspect the exteriors of ships and barges for marine growth,” Howell adds. “Barnacles and other marine growth can cost companies a lot of money because they slow down ships and barges. They also increase fuel consumption, compared to if their hulls are clean.

“I selected these machines because I’m very practical. I used to be a cowboy, so I’ve learned how to make do in a lot of different situations. As such, I appreciate innovation — and these machines eclipse anything else on the market.

“They’re moneymakers, too. They give us capabilities people are looking for, but don’t know about.”