Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

Inspection + Get AlertsPush camera and roller skid save time and money

Problem / By the time a plumber showed up at a home in Valatie, New York, the customer was stressed because the sewer pipe was backing up. No amount of plunging had worked and professional help was needed. An access plug in the pipe leading to the septic tank was easily accessible. Once removed, several buckets were used to collect sewage.

Solution / The plumber installed the CPI Products Trapmaster to get a 1.5-inch push camera into the 4-inch pipe and was able to pass by the remaining debris to view the blockage and determine exactly where it was. It turned out to be the last remaining section of a more than 30-year-old asphalt-coated paper pipe that had collapsed. They were able to pinpoint this by using the push camera with the roller skid.

Result / The collapsed section was easily accessed, and it saved time since digging up the entire pipeline wasn’t necessary. The repair was completed quickly, and the customer has a proper line all the way to the septic tank. 413-443-0925; www.cplasproducts.com

Software enhances crawler’s functions in pressurized pipe

Problem / Contractor Action Pipeline of Arizona was tasked by Tucson Water to detect and repair a leak in a pressurized 36-inch pipeline.

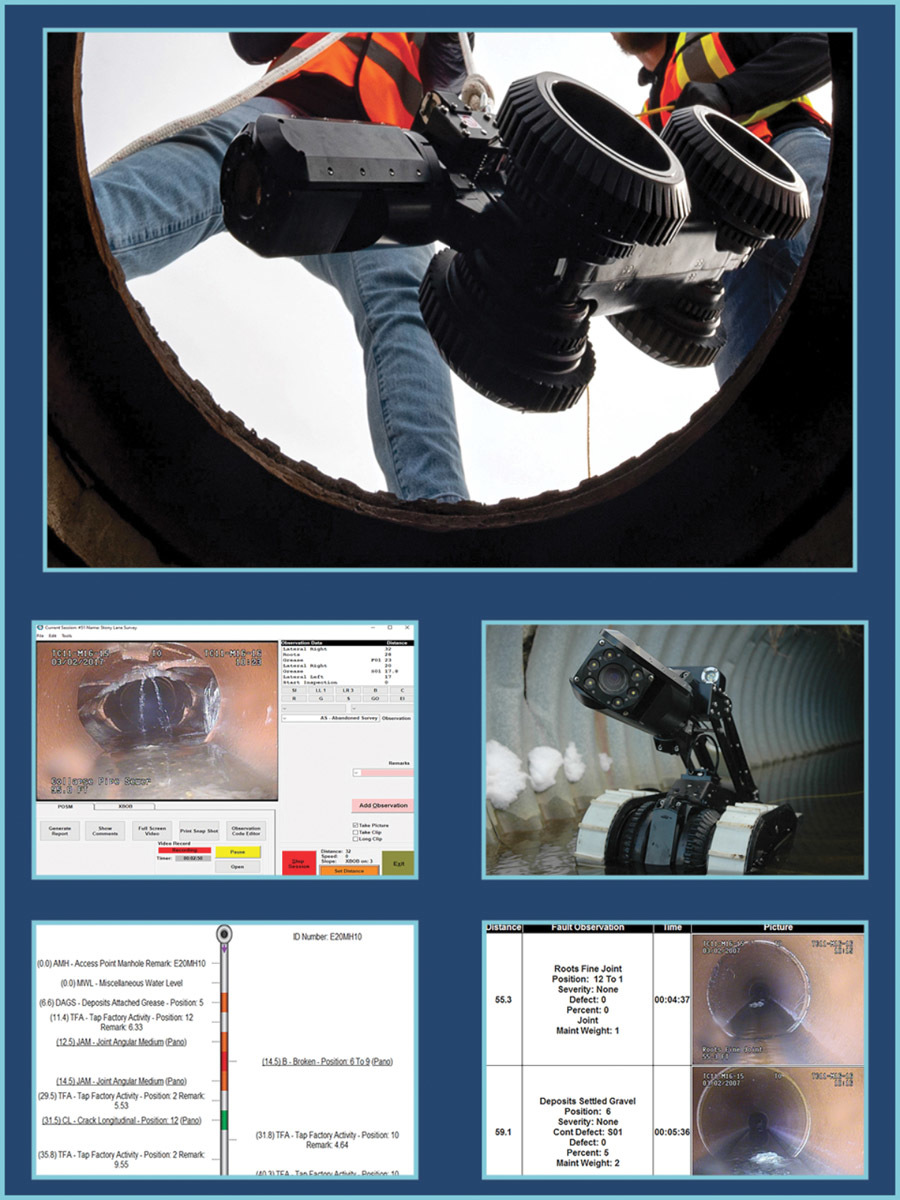

Solution / Given the inaccessibility of the deep-water environment, the company used its Deep Trekker DT340 crawler specially designed for such tasks. Action Pipeline controls the unit using POSM Lite Software. “Without Lite, you can’t edit or add comments to the Deep Trekker footage ‘live.’ Instead, you must review the video and add observations after the inspection is complete. That takes longer and is less efficient,” says Andres Amado, Action Pipeline’s vice president of operations. “Lite is a streamlined, inexpensive software that removes options we didn’t need. And, most important, it includes the ability to edit Deep Trekker video inspections live. We performed an internal investigation in the pressurized system. We installed an ink nozzle [onto the Deep Trekker unit] to seek and detect a leak ‘live’ thanks to POSM Lite. We inserted the robot into the pressurized pipeline and located a defect in the mortar. We injected the ink and watched it get sucked out of the pipe to document the spot in real time.”

Result / Because they paired Lite with their Deep Trekker, Amado says, “We were able to quickly and efficiently pinpoint the defect, dig it up and repair it.” 859-274-0041; www.posmsoftware.com