Interested in Relining/Rehab?

Get Relining/Rehab articles, news and videos right in your inbox! Sign up now.

Relining/Rehab + Get AlertsTechnology is taking over the world. It’s no different in sewer repair.

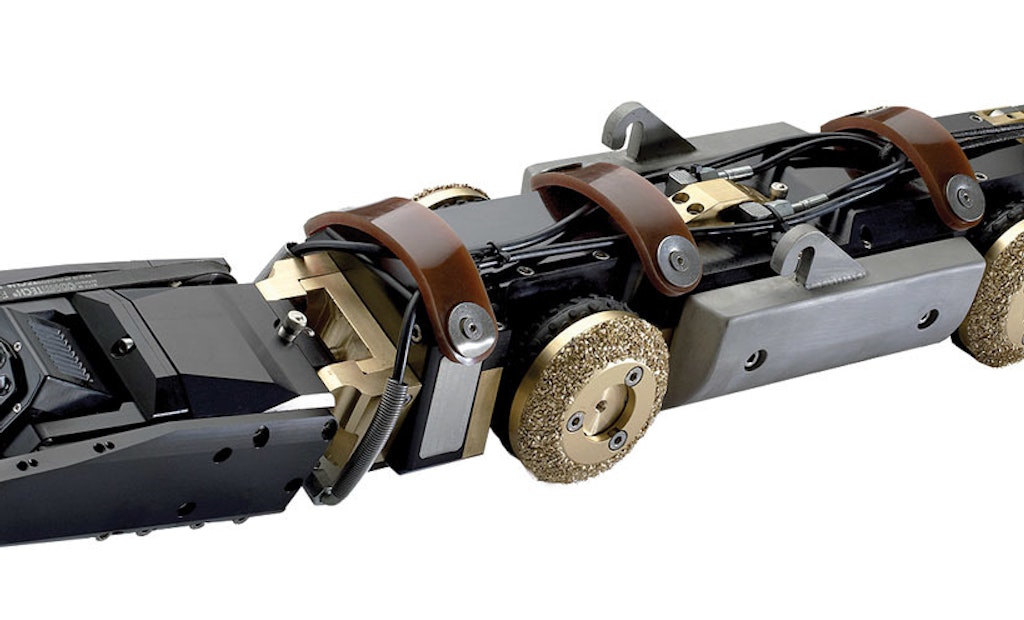

While many of the tried-and-true methods of line repair have remained constant for decades, sometimes a technological advancement can truly save time and make a technician’s job easier. That’s exactly what Schwalm Robotic USA is doing by introducing the Talpa FSR 1330 sewer robot to the U.S. market.

The German-manufactured sewer robot is designed for use in pipe diameters from 6 to 12 inches. The extent of the robot’s freedom of movement and thus its ability to reach all areas within its field of operation is critical to its range of applications. Its controls allow the operator to move the carriage forward and backward, rotate the working arm through 200 degrees on both sides, raise and lower the working arm, rotate the tool holder continuously through 360 degrees, pan the camera up and down, and control the lighting — all via joystick control.

“The Talpa FSR can be used for pretty much anything you need to do in a sewer but have trouble getting to,” says Casey Kane, national sales manager for Schwalm USA. “Most of the current applications where it is being used are in lining and pipe cutting.”

The Talpa FSR 1330 is equipped with a powerful LED spotlight and a high-resolution CCD color camera. The camera’s lens can be cleaned by remote control using an integrated cleaning device. The robot holds a stable position within the sewer pipe without needing to be additionally wedged or secured for its milling work. Its substantial weight and low center of gravity give it good surface grip, allowing it to be tilted to either side by more than 45 degrees on its longitudinal axis without tipping over.

“The contractors that are using these love their durability and that they are typically easy to repair,” Kane says. “Most repairs can be done in their own shop.”

Attachments such as milling heads, grinders and brushes are attached to the robot using a universal connection thread located on the air motors.

“We’ve found that contractors really love the number of attachments that are available on the Talpa,” Kane says. “It really is an easy-to-use, versatile product.” 864-414-9658; www.schwalm-usa.com.