Subsite Electronics utility inspection equipment is ideal for pipelines too small to allow man entry, including water and wastewater collections and conveyance systems. Solutions include CCTV, sonar profiling, 3D and point cloud data capture.

Mainline inspection equipment is routinely used by municipalities, water and sewer districts and contractors for inspecting 6-inch and larger sanitary storm drain sewer pipelines. Smaller pipelines, 4 inch and less, are typically inspected with a push camera system and are accessed from the sewer clean-out or other entry points inside the house.

During an inspection, data collection software is used to identify the assets being inspected, as well as log observations of defects and maintenance issues. The Pipeline Assessment and Certification Program has a standard coding system developed by the National Association of Sewer Service Companies. This tool is used for gathering common data that can be sorted by type of defect and severity of defect, and it allows an engineer to easily identify what pipes need to be addressed immediately and how to address the defect.

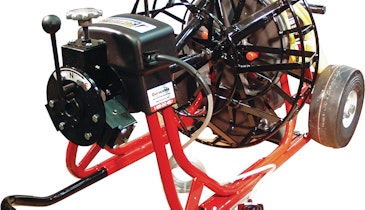

There are a few basic components of a CCTV pipe inspection system:

Camera or camera/transporter unit

Power supply/control unit

Reel and cable system

Much of Subsite’s CCTV equipment is built around single-conductor technology, which accommodates all power feed and command functions in a single steel-wrapped cable to make the equipment less bulky, easier to control and far more durable than typical multiconductor technology. The single-conductor technology is a version of the same coaxial cable that reliably delivers hundreds of TV channels, high-speed internet, voice communication and more to millions of households and businesses across America. The advantages over competitive multiconductor cable are clear:

Video signal quality is not affected by the length of cable, unlike multiconductor technology.

Single-conductor cables offer a life expectancy that is at least three times longer than that of any multiconductor cable.

Single-conductor cable has a breaking strength greater than 5,000 pounds, whereas typical multiconductor cable has a breaking strength of 2,000 pounds or less.

Single-conductor cable is simple to maintain, and the end connectors can be replaced in a matter of minutes. Multiconductor cable typically requires several hours of labor and advanced technical skills to splice or troubleshoot multiple wires.

To achieve maximum performance from the inspection equipment, quality training is a must. Factory trainers or certified trainers are the best solution to receive proper training for operation and maintenance of the equipment. Depending on the user’s experience, a mainline system training takes one to two days, and if additional equipment was purchased like a float system or a lateral launch system, an additional one to two days may be needed.

Subsite Electronics is committed to providing underground construction professionals the most comprehensive suite of electronic products in the industry, including utility locators, horizontal directional drilling guidance equipment, equipment machine controls, and CCTV remote inspection and monitoring cameras and accessories. By using innovative technologies, extensive market feedback and outstanding customer support, Subsite has established itself as the premier source of electronic technology to support the installation, maintenance and inspection of underground pipe and cable.

800-846-2713 | info@subsite.com | www.subsite.com