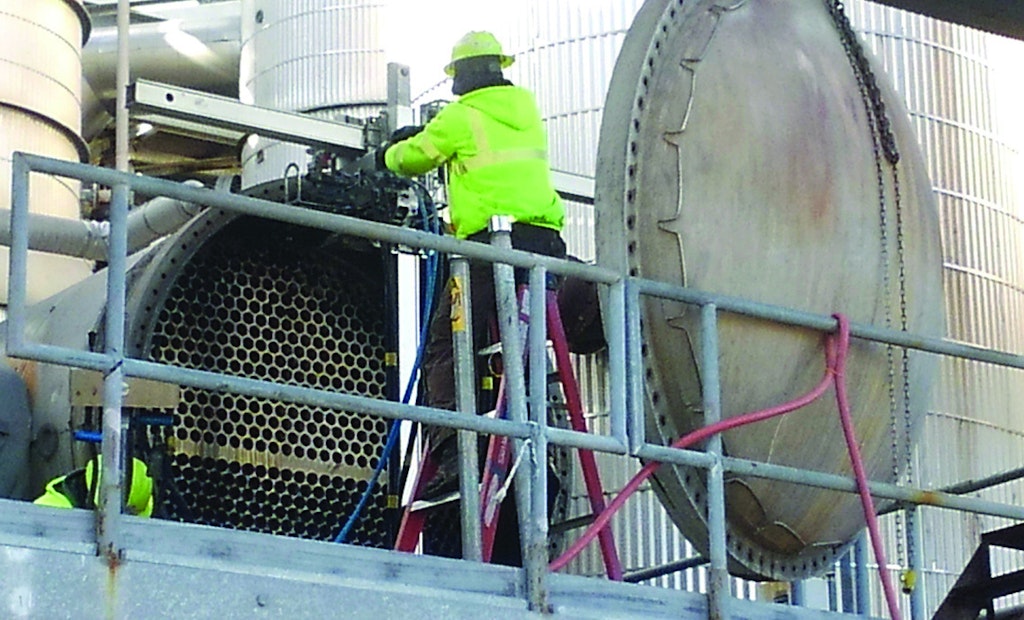

One of the benefits is a reduction in manpower. It takes only one or two people to run the machines, which can be set up in about 15 minutes by experienced workers.

Only three months after Ian Stewart purchased a ProPositioner lance tube cleaner in 2019, he ordered a second machine. And roughly six months later, he invested in yet another one.

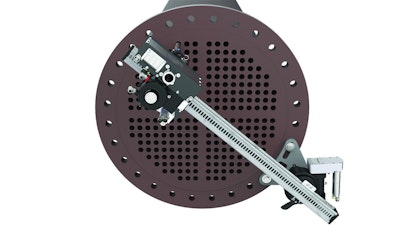

That’s a powerful testament to the benefits provided by the robotic machines made by StoneAge. The...