Interested in Relining/Rehab?

Get Relining/Rehab articles, news and videos right in your inbox! Sign up now.

Relining/Rehab + Get AlertsFor CIPP contractors, UV curing is becoming increasingly popular. From faster cure times to less styrene release, the UV method offers various benefits compared to other pipe lining cure options.

Here's a look at a few UV curing products available on the market.

Apex CIPP BRAWO SYSTEMS Magnavity SX

Magnavity SX from BRAWO SYSTEMS offers unique light curing. The compact system has a range of 197 feet. The two LED heads — Nano and Mega — enable the rehabilitation of diameters from DN 100 to DN 300 using BRAWOLINER and the vinyl ester resin BRAWO LR. The curing process is automated and the entire rehabilitation process is documented. It can rehabilitate longer pipes with bends with only one access point. The system is distributed in the U.S. through APEX CIPP Solutions. 941-300-0441; www.apexcipp.com

HammerHead Trenchless Bluelight LED

The redesigned Bluelight LED CIPP lining system for laterals and small drainpipes from HammerHead Trenchless uses a specially formulated resin that only cures under light in the “blue” wavelength, giving installers a significantly longer working time between liner wet-out and curing. Once installed, the automated curing system pulls the LED light head through the liner, curing the resin almost instantly — up to five times faster than other methods. Instead of waiting hours for the liner to cure, a 50-foot sewer line could be fully cured in under 10 minutes. 800-331-6653; www.hammerheadtrenchless.com

Omega Liner

Omega Liner is a high-strength GRP UV-cured liner for trenchless rehabilitation of water, wastewater and stormwater piping systems. It is constructed with ECR (corrosion-resistant) fiberglass and advanced UV resins, and uses unsaturated polyester or vinyl ester resins for environmentally conscious projects. It is offered for both circular and non-circular pipes from 6 to 66 inches, has a 6-month shelf life, conforms to ASTM F-2019, and meets and exceeds ASTM F-1216. Factory training and support is available, with a small equipment footprint and increased efficiencies. 605-558-1020; www.omegauvpipe.com

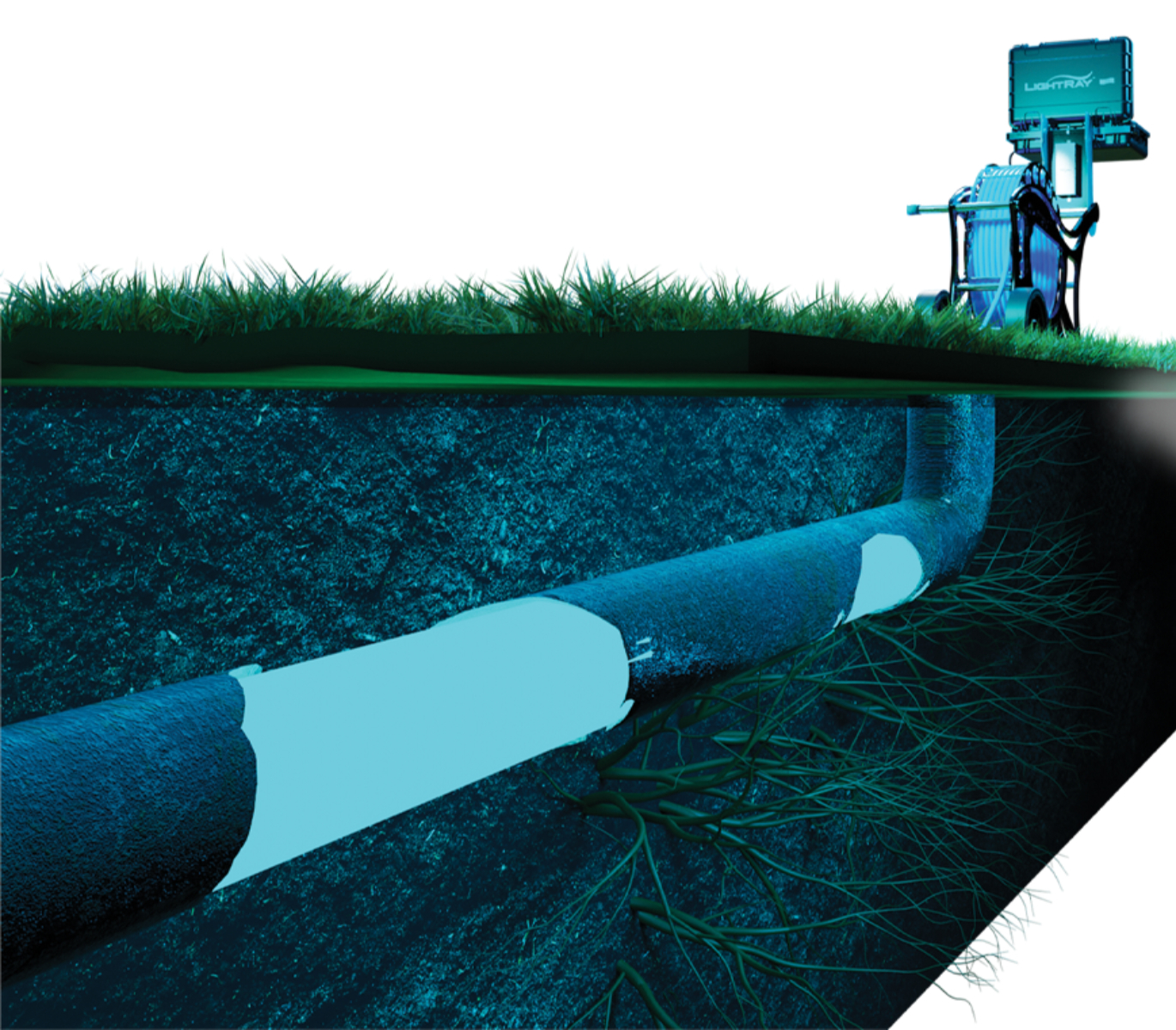

Waterline Renewal Technologies LightRay LR3 LED UV

The LightRay LR3 LED UV system from Waterline Renewal Technologies is an advanced UV cast-in-place pipe technology allowing complete operator control of the casting process. It is both a push- and pull-in-place spot repair system, providing the flexibility to perform both operations by only changing the cold LED repair packer. The non-VOC resin is pre-impregnated into the high-performance fiberglass liner and shipped ready to install for no-dig pipe infrastructure repairs. Once the install site is prepped, casting times in under 10 minutes can be achieved, eliminating the risk of premature or prolonged casting times due to temperature variations. It repairs pipe diameters of 3 to 12 inches, including transitions. 847-457-1810; www.waterlinerenewal.com