Interested in Waterblasting?

Get Waterblasting articles, news and videos right in your inbox! Sign up now.

Waterblasting + Get AlertsBasic troubleshooting can help solve some of the pressure issues that can afflict any jetter from time to time: low pressure, loss of pressure or pressure spikes. These issues can be caused by a few different things, most of which have simple fixes. These three steps are a good place to start your diagnosis:

1. Check the nozzle. Any nozzle that is clogged or in need of repair will have an effect on pressure and volume. For drilled nozzles, use a nozzle cleaning tool to clean out its orifices, being aware of the angles of the jet openings. For nozzles with inserts, follow the manufacturer’s recommendations for checking the nozzle, you may need to check rotation as well as the inserts. Also be sure the nozzle is sized correctly for the jetter’s pump. Using a nozzle that is either too large or too small can adversely affect pressure. Once you’ve checked and cleaned or repaired the nozzle, reattach and power up the system to see if that solved the problem.

2. Test the water supply (if possible). Jetter pumps require a certain flow rate for supply water in order to function properly. Check your owner's manual to find the gallons per minute capacity for your model. To test the supply, run a hose from the water source into a 5- or 10-gallon bucket for one minute. If the number of gallons in the bucket after one minute falls short of the required gpm rating, then your jetter is not receiving enough water from the source, which will adversely affect its spray pressure.

3. Test the water supply through the jetter. If your nozzle is clear and the supply is sufficient, then test the flow through the jetter hose. Perform the one-minute bucket test again using the jetter hose without a nozzle attached. If the jetter is still producing the appropriate gpm, other issues could be the problem.

A leaking jumper hose, or the ball valve that connects the jumper hose to the high-pressure hose, could be the culprit. Inspect those.

Know the size and length of hose that is optimal for the jetter to perform correctly. The longer the hose, the lower the pressure at the nozzle. Be sure to follow both jetter and nozzle manufacturer’s recommendations for hoses.

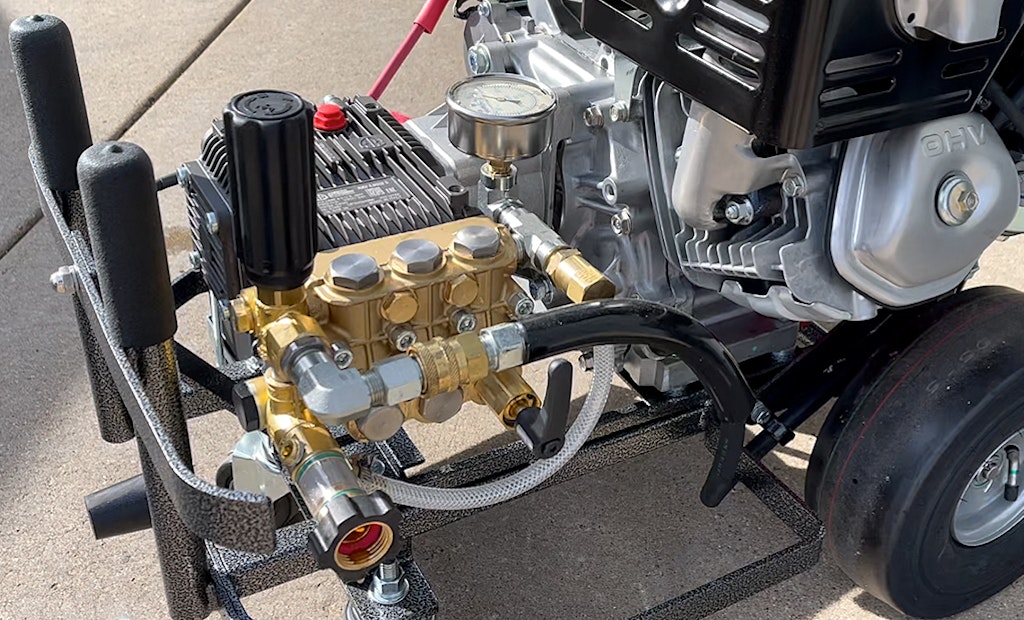

Finally, the issue could be in the pump itself. New noises or milky/cloudy oil in the pump could indicate a cracked ceramic plunger or bad seals. Other problems in the pump can cause drops in pressure and performance as well.

MyTana backs all its equipment with factory-direct support. Request a catalog to learn more about MyTana’s family of jetters.