Interested in Relining/Rehab?

Get Relining/Rehab articles, news and videos right in your inbox! Sign up now.

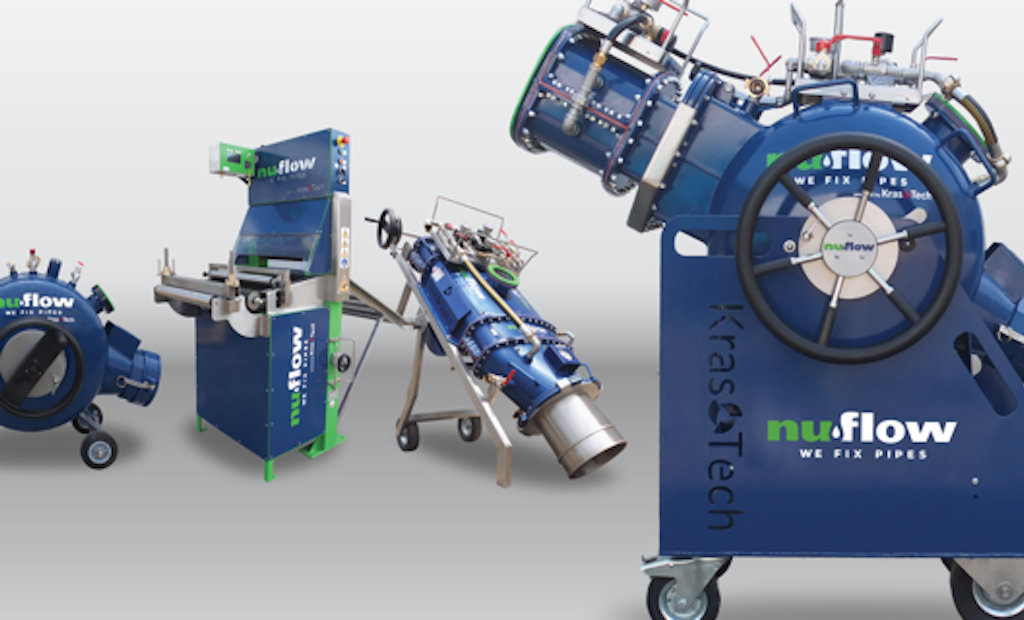

Relining/Rehab + Get AlertsNuFlow aims to provide its network of Certified Contractors with the highest quality materials, technology and know-how to repair the worst pipe system failures imaginable. The right equipment makes contractors more competitive in the marketplace, so they win more jobs. NuFlow has teamed up with German-based KrasoTech GmbH to introduce the NuTube Inversion lining system. These tools provide the options for contractors to tackle every pipe lining problem out there, from small diameter in-building, to long, straight, larger diameter runs.

For over 20 years, KrasoTech has provided innovations for pipe renovation equipment to its partners across the globe. Equipment is constructed with the operator in mind, creating user-friendly materials that provide full control of the lining process and enhanced safety features.

The NuTube Drum Inversion Hybrid features a sluice module attachment that enables pipe rehabilitation of distances beyond the capacity of the drum, creating one device with endless inversion capabilities. The innovative piece of machinery features an easy click flange system without screws or clamps — for a guaranteed faster, easier and safer seal. Plus, a power shot function helps with especially difficult bends. The product can utilize air, water, steam and light curing for diameters of up to 9 inches.

NuTube Drum Inversion Light is a simple but smart inversion drum. Its lightweight aluminum body is ideal for job sites with restricted space. Suited for up to 8-inch-diameter pipes, it works with air, water, steam and UV curing and features an angle adjustment with two standing positions, safety valves and two viewing windows.

NuTube Sluice Inversion includes a patented two-chamber system for endless inversion without pressure loss to protect the liner from unwanted stretching, bruises, wrinkles and folds. Even large nodes, fittings or heating hoses are no problem for the NuTube Sluice. Direct inversion with low pressure and without wind up, it also includes a power shot function for difficult bends and it significantly reduces the longitudinal expansion of flexible liners. It’s capable of inverting diameters up to 12 inches utilizing air, water, steam and UV curing.

The Electro-pneumatic Calibration Unit is a compact unit made of high-quality aluminum and stainless steel. The product features synchronized drive of calibration rollers with speed adjustment variables and drive rotations both forward and reverse. The automatic electro-pneumatic closing and opening of the roller enhances safety, and a memory function on gap adjustment enables precision control. The product is developed for on-site installation setups inside vehicles, trailers or work halls. Includes data documentation of date, time, job site, employees, customer, liner data, resin data, impregnation speed, rotation direction, gap adjustment, warnings, error reports, vacuum data for job quality assurance and software integration for NuFlow’s mixing and curing systems.

NuTube Inversion equipment is engineered to the highest possible standards with the finest German craftsmanship and is third-party tested to three times its working pressure. All NuFlow equipment comes with comprehensive training and true 24/7 job support.

Visit the NuFlow Technologies Storefront