Interested in Relining/Rehab?

Get Relining/Rehab articles, news and videos right in your inbox! Sign up now.

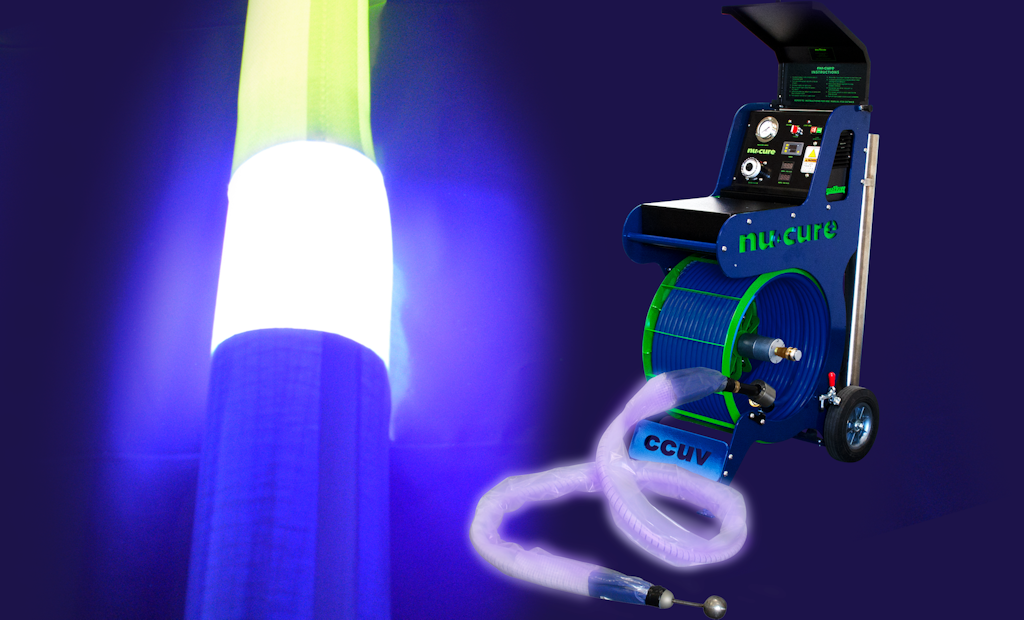

Relining/Rehab + Get AlertsIn developing the NuCure Cold Cure UV system, the engineering team at NuFlow calculated specific requirements to cure three-layer fiberglass material, measuring the optical power density as a function of different voltages applied to LED strips. Differential scanning calorimetry determined the percentage of liner cured as a function of irradiance, resulting in the precise micro-watts per centimeter squared calculation, and its power requirements, to ensure complete irradiance and full curing of the length of the liner, from end to end.

The results were integrated into the design of NuFlow’s NuCure Cold Cure UV lining system. NuCure CCUV features an enhanced Double Helix light rope for a reliable and dense cure, while the dual power supplies ensure light power will fully penetrate the entire liner. The LED light emitters significantly lower thermal emissions and are more efficient than phosphorous bulbs used in large-diameter light trains.

The NuCure system leverages proprietary cold cure resin technology that has many advantages over legacy CIPP resins. Cold cure resins cure densely in as little as 10 minutes, speeding installation times and limiting the duration of thermal energy release. The resin is shelf stable for a minimum of 10 months, allowing the contractor to pre-wet-out months in advance. Just recalibrate and the liner is ready to use. And zero VOC avoids nuisance odors and resident concerns at the job site.

NuCure’s Resin Protection System protects the resin from sunlight or UV exposure, so the installer can work without fear of premature curing. The Resin Protection System consists of an integral UV barrier outer coating, which offers high thermal stability, and a removable inner calibration bladder that assists with containing and evenly distributing the resin. In addition to protecting the resin from sunlight exposure, it protects against excessive bleed-out, blow-out, wash-out, emulsification and resin slugs.

NuCure Cold Cure UV combines proprietary Double Helix light train, the innovative Resin Protection System, and NuFlow’s signature Precision Push or Pull-in-Place installation method to create an evolutionary leap in light curing technology.

Visit the NuFlow Technologies Storefront