Not all light-cure technologies (UV or otherwise) are created equal. Illumination source, wavelength, intensity, motion, heat and other factors impact performance in a variety of ways. Here we benchmark PRT's SpeedyLight+ (small diameter) and LEDRig (large diameter) against competing light-cure technologies.

It should be noted that all technologies compared here offer the benefits of light cure, which include no mixing, no styrene, faster cures, extended working life and shelf life, and the option for remote or on-site wet-out.

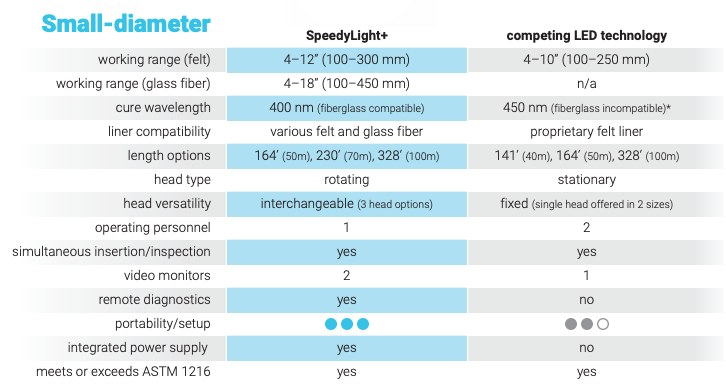

The chart below compares SpeedyLight+ to a competing LED-based technology. Small-diameter applications present challenges to which SpeedyLight+ is particularly suited: bends, transitions in diameter, vertical orientations and indoor deployment.

“Compatible” refers to the ability to cure most common pre-impregnated glass-fiber liners on the market.

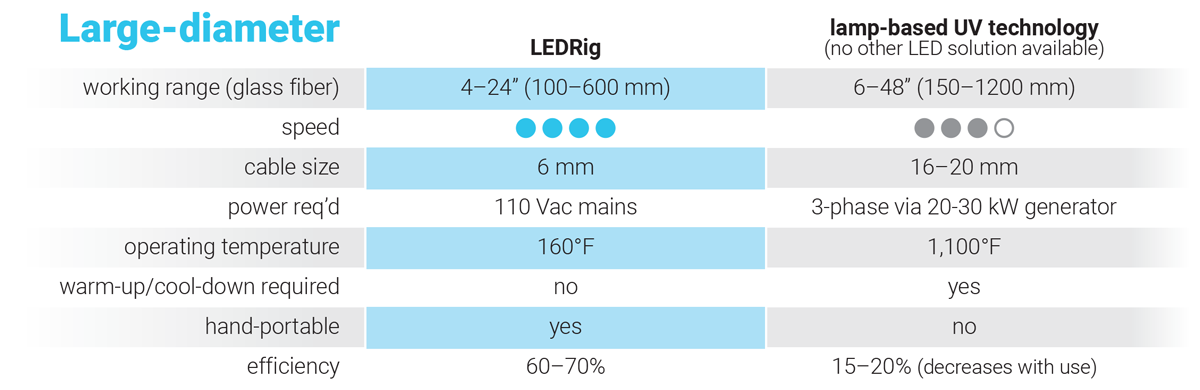

For large-diameter applications, PRT benchmarked its LEDRig product against lamp-based UV, as there are no alternative LED-based technologies for large-diameter CIPP.

The information above is available for download as a reference page. Ultimately, choosing a light-cure technology takes careful research followed by field trials. If you're ready for a field trial of SpeedyLight+ or LEDRig, simply click below and enter your information in the form provided — Pipeline Renewal Technologies will be in touch to schedule one.

Visit the Pipeline Renewal Technologies Storefront