The CUES SPiDER scanner is the only wireless, color, manhole inspection technology in the industry with a lightweight and compact form, according to Pierre Mikhail, director of the CUES Manhole Inspection Division.

“The SPiDER scanner provides a new outlook on how manhole data is collected and applied,” Mikhail says. “While other cameras and inspection devices use a payout reel to determine how deep the camera is in a manhole, the 40-pound, tetherless, self-contained SPiDER typically is deployed using a telescopic mast or tripod for stability.

“It is operated with a tablet computer that controls the scanners and lights. This technology frees manhole scanning from problems associated with inaccurate, poorly calibrated cable counters and poorly managed cables. SPiDER does not require a truck or data/power cable for operational use. Scanning data is recorded on the camera unit and not on the tablet.”

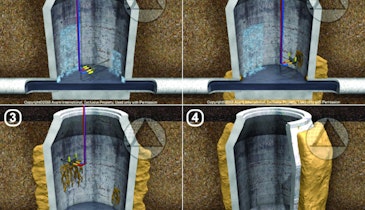

SPiDER collects millions of 3D points during each manhole scan that provides engineering and survey quality information about manhole geometry and condition. Information gathered can be used for structural assessment, pre- and post-rehabilitation analysis, hydrological surveys and general condition assessment.

SPiDER produces 3D, textured point cloud renderings of manhole geometry to provide 3D visualization that can be imported into a wide range of 3D viewers and delivered in several file formats:

3D MPEG video (MPG)

Point cloud (PLY), which can be converted to surface model (STL), CAD model (DXF) and virtual model (OBJ)

Manhole report using your preferred manhole inspection software

190 degree field-of-view live video stream, an ideal tool for infiltration and inflow studies, which depend on live video to detect moving water

SPiDER also produces a variance report between two scans, resulting in a heat-map type of output to evaluate how much the structure has varied between scans. This makes SPiDER the first tool available to assess the quality of rehabilitation in vertical structures.

In addition, the SPiDER and other CUES manhole inspection equipment can be used with a CUES Manhole Inspection Vehicle, or MIV. Use CUES MIVs to determine where to perform rehab and CCTV inspections and to reduce costs and save time by prescreening pipeline conditions during the manhole inspection — up to 40 manholes per day. CUES MIVs eliminate the picture quality and production limitations of traditional hand-held, cable or tripod manhole inspection systems.

The CUES MIV is designed to operate all CUES manhole cameras with a user-friendly, interchangeable mounting bracket. The MIV is the only vehicle in the industry that can inspect and scan most types of structures including sanitary/storm manholes (up to 50 feet deep), sanitary/storm pipelines (6 to 120 inches in diameter), lift stations, gravity interceptor pipelines (without bypass pumping), vaults, outfalls and more.

As the world’s leading manufacturer of water, wastewater and stormwater inspection equipment, CUES provides the necessary tools for both pipeline inspection and repair. For 50-plus years, CUES has manufactured the most rugged and reliable pipeline inspection equipment in the industry. CUES also offers a range of advanced systems, such as SONAR, LIDAR and LASER PROFILING, for those requiring more detailed inspection data.

800-327-7791 | salesinfo@cuesinc.com | www.cuesinc.com