NuFlow Technologies has teamed up with Pro-Kanal to introduce its newest technology, NuCure Cold Cure UV (CCUV), the original true cold cure UV-LED system. Pro-Kanal has been supplying its Double Helix, low-voltage LED UV light core technology to the market since 2016. By combining Double Helix technology with NuFlow’s Cold Cure UV resins, we’ve created an evolutionary leap in light curing technology.

WHAT MAKES NUFLOW’S UV-CURED LINING DIFFERENT?

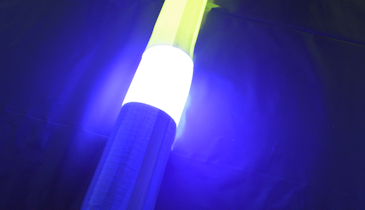

Proprietary Double Helix light core assembly

NuFlow’s unique Double Helix CCUV technology ensures that light penetrates the entire surface of the liner. The Double Helix design entwines multiple LED light ropes into 3-, 10- and 30-foot CCUV light cores to cure the CCUV resins while creating a redundancy to ensure there are no disruptions during the process. The liners are also available as wyes and tees for lining branch connections, allowing for the full structural rehabilitation of a piping system. The LED light emitters significantly lower thermal emissions and are more efficient than phosphorous bulbs used in large-diameter light trains. Reducing the thermal emissions is a key factor to eliminate the need for a larger footprint and additional equipment such as high cubic-feet-per-minute ventilation and air drying.

Cold cure resin technology

NuCure CCUV resin offers many advantages over the legacy cured-in-place pipe resins. The CCUV resins are shelf stable, allowing the contractor to wet-out on site or offsite; provide a longer pot life; and enable exceptionally fast UV cure times. NuFlow’s CCUV resins cure densely within 10 to 20 minutes, drastically reducing installation times and limiting the duration of thermal energy release. The low temperatures and durations mean NuCure CCUV liners can be installed within thin-walled plastic pipes, which could not be lined with other CIPP technologies. In addition, the resins have zero VOC, avoiding nuisance odors and resident concerns at the job site.

NuCure glass-fiber reinforced

plastic liner tubes

NuFlow’s NuCure GRP liner tubes are engineered for performance. These seamless, radially expandable, electrochemical resistance fiberglass tubes are engineered to conform to bends and size transitions. Utilizing NuFlow’s Precision PIP (push- or pull-in-place) installation methods enables the CCUV to achieve reliably accurate placement without any cumbersome inversion equipment or complex robotics.

The ECR glass features inherent corrosion resistance, while the fiberglass reinforcement provides a thin-wall, high-strength structure to avoid flow loss. The Resin Protection System consists of an integral polyurethane outer coating, which offers high thermal stability, and a removable inner calibration bladder. The bladder assists with containing and evenly distributing the resin; protecting the resin from excessive bleed-out, blowout, washout and emulsification; and preventing resin slugs.

800-834-9597 | info@nuflowtechnologies.com