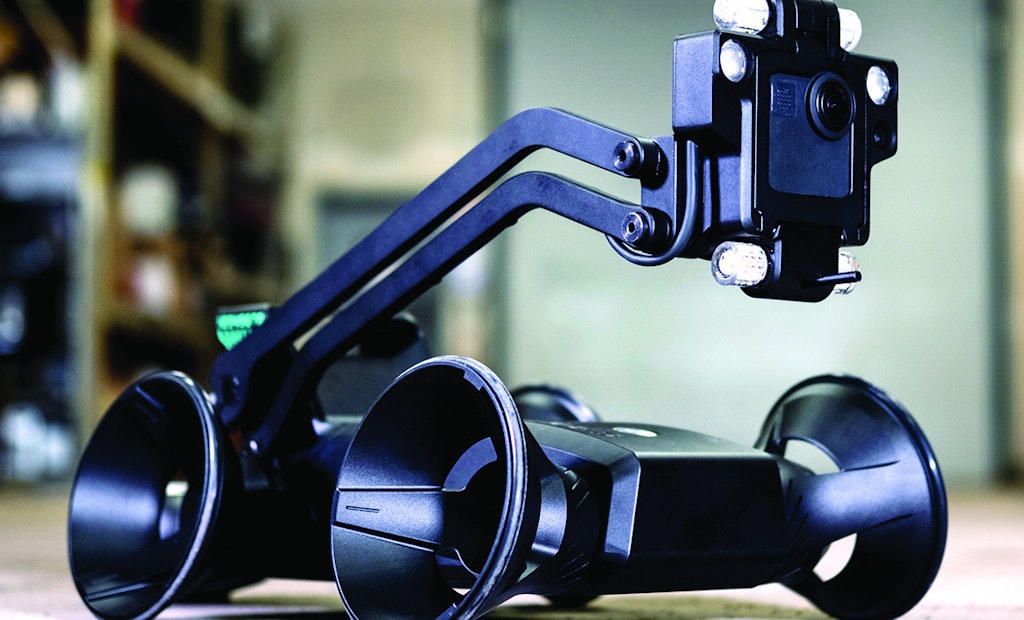

Municipalities are constantly on the lookout for ways to optimize budget and increase efficiency. Can-Ex Technologies provides cities and towns with the means to efficiently monitor and survey sewer system assets by centralizing their inspection data through use of the ZIPCAM...

Product Spotlight: Camera system streamlines cleaning and inspection process

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.