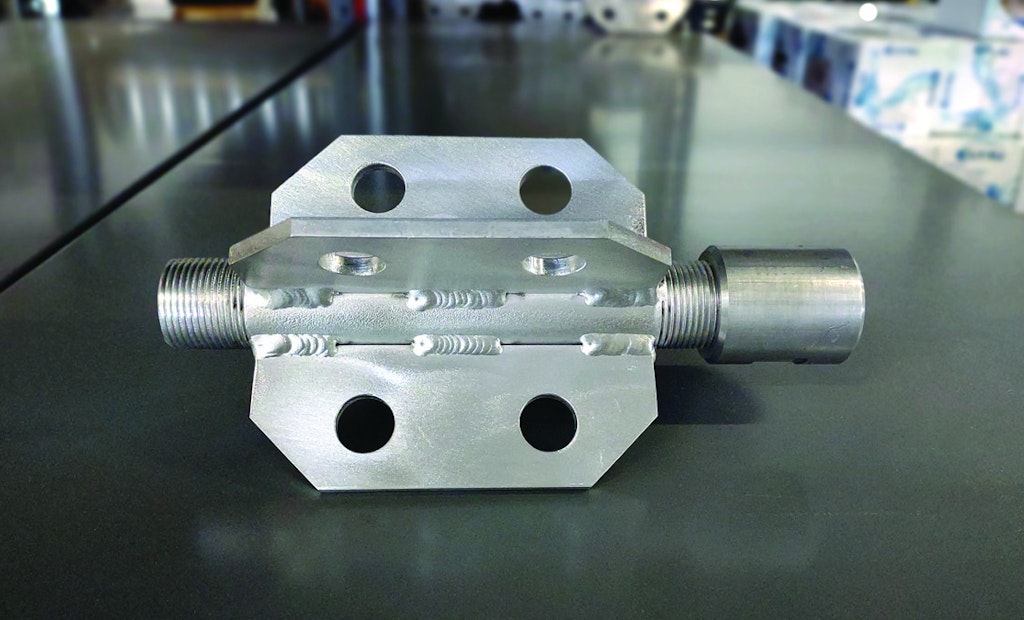

Using a high-performance aluminum nozzle with an aluminum skid can provide approximately 30% more power than typically available through conventional options.

For municipalities and contractors who clean endless miles of sewer lines, the goal is always to clean more with less effort and fewer resources.

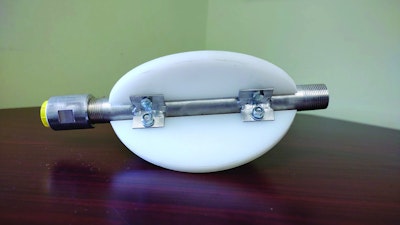

Making that goal attainable is innovation in lightweight skid nozzle stabilizing attachments, enabling cleaning crews to move through...