Inspection and cleaning of a drain system typically requires multiple tools — namely the high-pressure drain cleaner first, followed by the camera inspection.

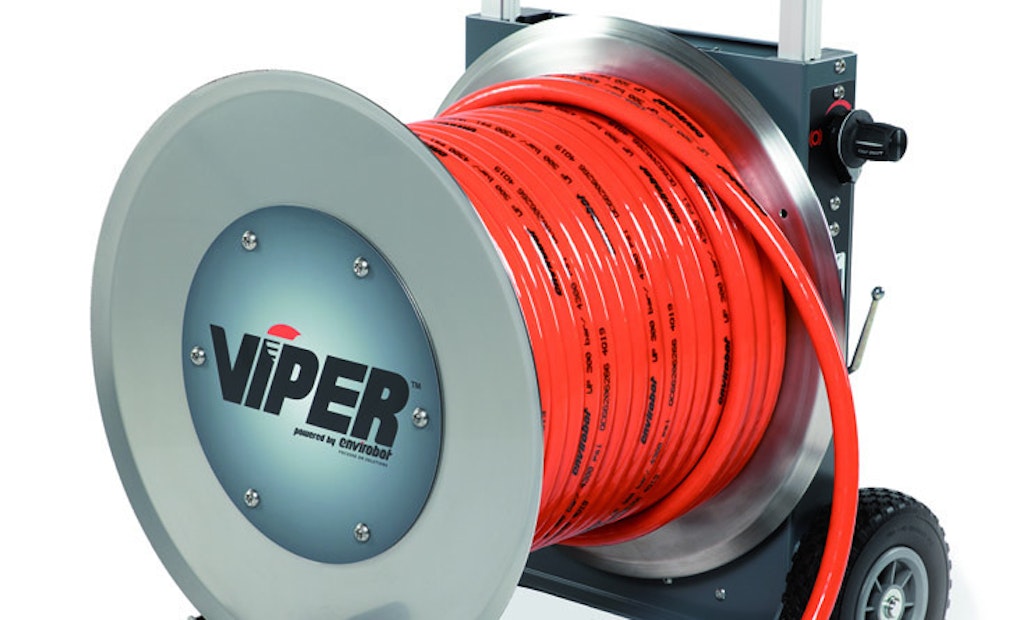

The VIPER is a pipe and sewer cleaning system that saves time, money and resources by combining the two needs into one...