To avoid tendonitis in the index finger, otherwise known as “trigger finger,” good ergonomic tools should allow for the use of two or three fingers to activate switches to reduce discomfort and minimize the risk for injury.

Interested in Safety?

Get Safety articles, news and videos right in your inbox! Sign up now.

Safety + Get AlertsNot long ago a tool’s impact on its user was not given much thought. The expectation was that the trade professional would adapt to the tool, not the other way around.

Today, that reality has shifted. Manufacturers take the time to observe and understand the user’s experience to find new ways to enhance tool ergonomics. These insights, combined with a better understanding of ergonomics and advances in technology, are allowing for the development of more thoughtful, ergonomic tools. For example, new technologies have reduced the size and weight of tools. Brushless motors, battery technology and changes in material application have led the way for more ergonomic designs.

If you are considering swapping out older tools for newer ergonomically designed ones, think about the various benefits. For example, an ergonomic tool provides trade professionals:

Peace of mind

- No tradesperson wants to come to work thinking that they might get injured during their workday, particularly not by their tools. Providing well-designed ergonomic tools ensures that the individual is healthier, less stressed and looks forward to their workday.

Reduced body strain

- Ergonomic tools are designed to align with the body’s natural movement so that they have as little effect on the body as possible. It reduces the likelihood that users will suffer strains or sprains after a day of working in confined or difficult positions.

Enhanced job performance

- Ergonomic tools increase job efficiency. Wasted motions are less likely when an individual uses ergonomic tools, allowing the worker to get more done in the same amount of time. And because ergonomic tools are designed to work with the body, you likely will not need to take breaks as often due to aches and pains, which also increases efficiency.

Improved job capabilities

- Ergonomic tools can increase a worker’s capabilities. Using the tools in natural positions means they will not lose power bending and twisting, which allows them to do more than they might using non-ergonomic tools.

BUSINESS BENEFITS

The benefit is equally significant for a business. The science of ergonomics has proven that if tools cause pain, discomfort, or distraction from a job in some way, it will affect a company’s productivity, the health of its employees, and the company’s bottom line. Businesses are finding ergonomic tools that result in:

More engaged employees

- When a company provides employees with a properly designed, ergonomic tool, employees will notice the company is committed to their health and safety. Reducing employee fatigue and discomfort can reduce turnover, decrease absenteeism, improve morale and increase employee involvement.

Fewer errors

- If an employee is distracted by pain or fatigue caused by their tools, it leads to mistakes, and mistakes lead to downtime and cost. Having employees focused on their work ensures fewer errors and keeps the employee engaged.

Increased productivity

- The more focused employees are in doing their job, the more productive they are. Ergonomics can make all the difference. Ergonomics are meant to make things feel safer and more natural, and not distract the employee from their work. When the body is less strained, especially in the case of repetitive motions, the health of employees will improve.

FEATURES TO LOOK FOR

As ergonomic tool design becomes the standard, understanding basic ergonomic features to look for when making a purchase will help ensure you are investing in the best equipment for your team.

Two initial features to look at are the size and weight of the tool. Advances in technology are enabling tools to become smaller and lighter, both minimizing strain and fatigue for the user while increasing productivity on the job site. Looking for the smallest and lightest tools to meet the demands of your typical jobs is ideal.

Beyond these two key areas, additional features to look for are:

- Tools that are well balanced, lightweight and can ideally be operated with one hand. The weight will vary depending on the use of the tool.

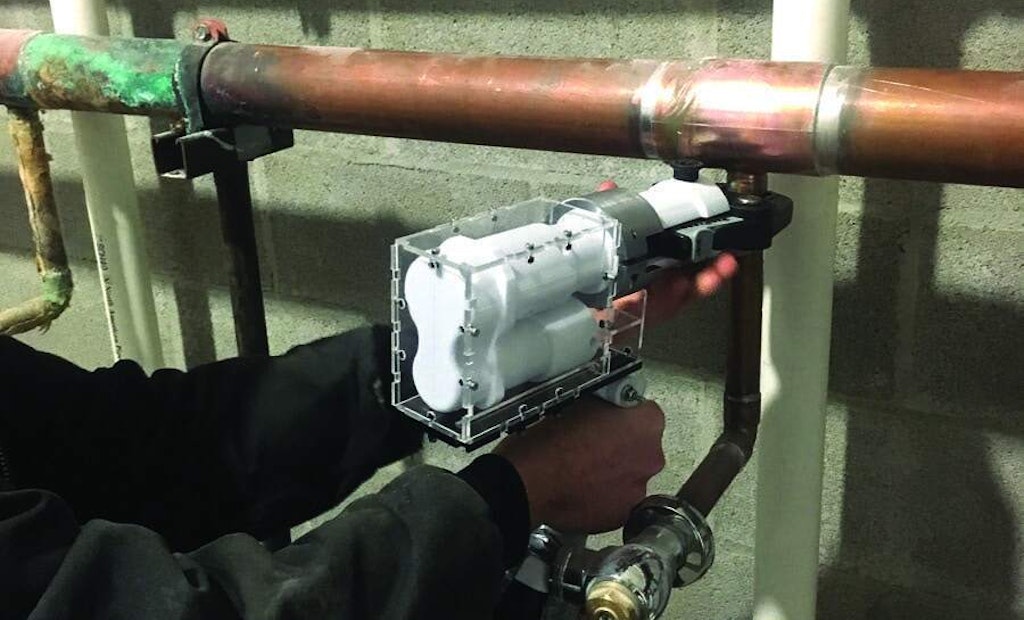

- In the case of hand or press tools, the center of gravity should be aligned with the center of the gripping hand. In other words, the tool should feel “easy” to hold either in an upright position or in the position it will be used.

- For tools being used for precision work, the handles and grips of hand tools should have a “power grip.” Handle diameter recommendations vary, but in general, cylindrical handles at 1 1/2 to 2 inches offer a better power grip. For precision grips, a diameter of 1 1/4 inches is recommended. The larger diameter will allow for maximum torque, while the smaller diameter helps with dexterity and speed.

- To ensure a good grip on a handle, sufficient friction must exist between the hand and the handle and remain consistent even with a sweaty hand. Hand tools should be made of nonslip, nonconductive and compressible materials such as textured rubber that help keep the tool from slipping out of the hand.

- To avoid tendonitis in the index finger, otherwise known as “trigger finger,” look for solutions that allow for the use of two or three fingers to activate switches to reduce discomfort and minimize the risk for injury.

- Large drain cleaning tools should feel balanced during transport and use. Use proper lifting and form when maneuvering stairs or into work vehicles to avoid injury. When in operation, any information the user might need should be visually accessible and large enough for the user to see. Smaller, handheld drain cleaners should feel comfortable when managing the cable to ensure the user is in control.

- Minor aches and pains add up over time, taking individuals off the job site for injuries or down a different career path entirely. Using tools with even just a few of the above features will go a long way in reducing this physical strain and injury.