Pipeline cleaning and surveying can be time-consuming and labor intensive. But technological advancements are helping to streamline the process.

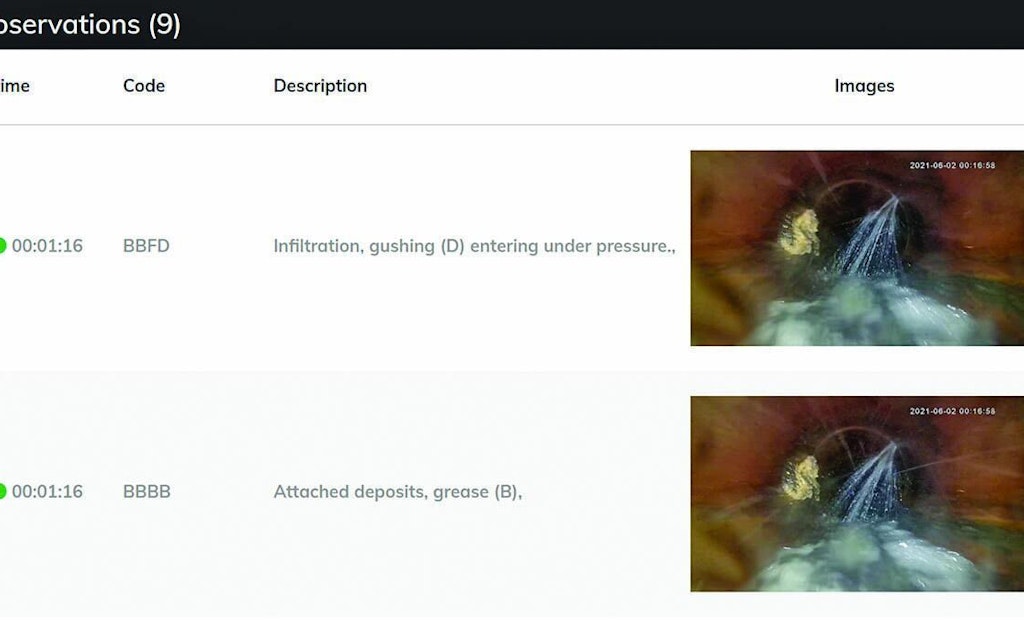

Sewer Robotics recently announced automatic defect coding powered by artificial intelligence, essentially taking the task out of the...