Relining and Rehabilitation Systems

Permanent lateral sealing system

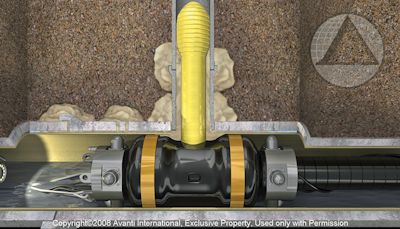

Top Seal from AMerik Engineering is for permanent lateral sealing of the gap between the liner and the existing pipe. The system places a pre-impregnated fiberglass insert in the lateral junction, and UV...