Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

Inspection + Get AlertsChoosing or changing a defect catalog can have far-reaching implications for regional infrastructure. A smart approach to standardization increases efficiency and reliability and allows an organization to plan and strategize for the future — rather than respond to crises as they occur.

Today there are many different standardization systems available, but two dominate much of the international market. The first real defect catalog came from the U.K.-based Water Research Centre. In the 1980s, it introduced the Manual of Sewer Condition Classification, a national standard defect coding system for the country’s varied underground water infrastructure. It outlined a shared language for contractors, maintenance teams and municipal leadership to ensure consistency and mutual understanding. The system specified abbreviations and designations for various kinds of damage and maintenance problems, from grease buildup to collapses. Each inspected section of pipe was scored from 1 (no defects) to 5 (collapsed section or collapse imminent) based on defect severity.

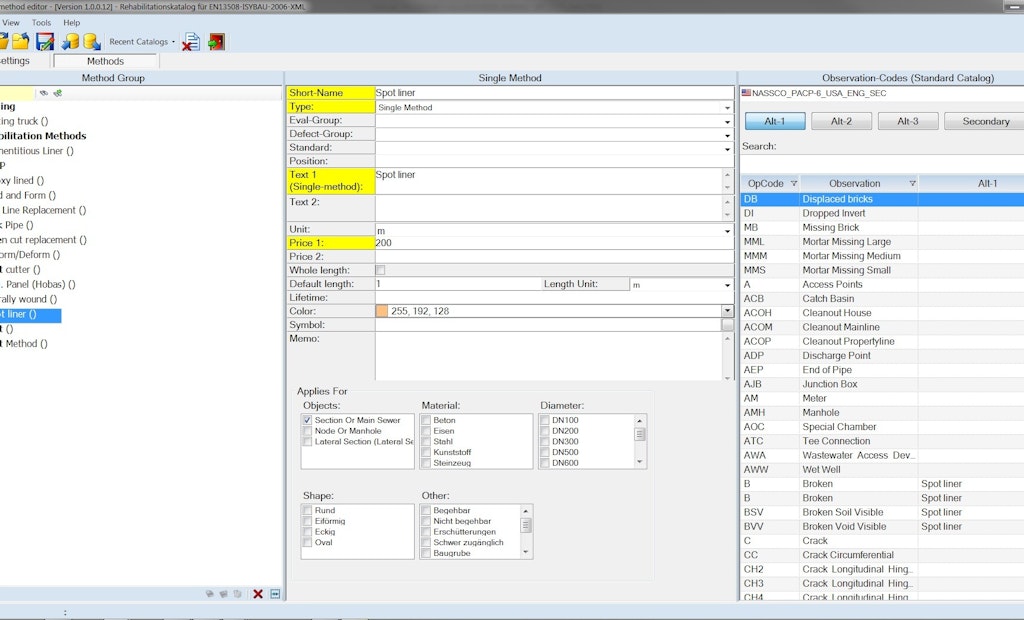

The success of the WRc attracted followers around the world, but the MSCC was not without its challenges. In North America, engineers struggled to make heads or tails of the language, which exposed regional variations in terminology and practice. In response, many organizations and regional authorities set about developing their own codes, many inspired by the MSCC. Some are still used today in major metropolitan areas across the U.S. and the world. The National Association of Sewer Service Companies’ Pipeline Assessment Certification Program, or PACP, was developed in collaboration with WRc nearly two decades ago. Designed specifically for American users, it has since been adopted in municipalities across both North and South America in English, French and Spanish language versions and has approximately 20,000 certified users.

Today, the MSCC is on its 5th version, while NASSCO released PACP 7.0 in 2015. They have more similarities than they do differences, and the need for efficiency, consistency and standardization continues to drive users of both systems. Each is constantly evolving to meet the changing needs of the industry and the ever-expanding range of inspection technologies.

As North America’s infrastructure ages and environmental demands become more stringent, many organizations have identified defect catalogs as a way to improve efficiency and demonstrate compliance. Envirosight makes it easy to ensure your observation data aligns with industry standards. The VC500 controller for the ROVVER X sewer inspection crawler allows users to build standards-compliant inspection reports directly from the system’s interface. When you upload inspection footage and data from your controller into an asset management software like WinCan, Pipelogix or any other PACP-certified solution, there’s no need to code defects; your data becomes PACP-certified, too.

To learn more about the benefits of PACP, download Envirosight’s white paper, 5 Things You're Missing Without PACP: Download now.