Interested in Relining/Rehab?

Get Relining/Rehab articles, news and videos right in your inbox! Sign up now.

Relining/Rehab + Get AlertsThe market for pipe repair and rehabilitation is large and growing. Based on U.S. EPA analyses, the public and municipal small-diameter distribution systems market is estimated to be more than $3.9 billion per annum. The market for infrastructure repairs to private plumbing systems is estimated to be as much as “five to 10 times larger [than the public market]” — an additional market opportunity of as much as $39 billion per annum.

In the private market sector, the small-diameter pipe lining market has been almost exclusively serviced by plumbing and mechanical engineering contractors re-piping old pipe systems. However, since early 2000, pipe lining companies have emerged with a more practical and cost-effective alternative to traditional replacement. Rehabilitation versus replacement is a recurrent theme in reports and studies conducted by private and governmental authorities tasked with finding solutions to infrastructure failure.

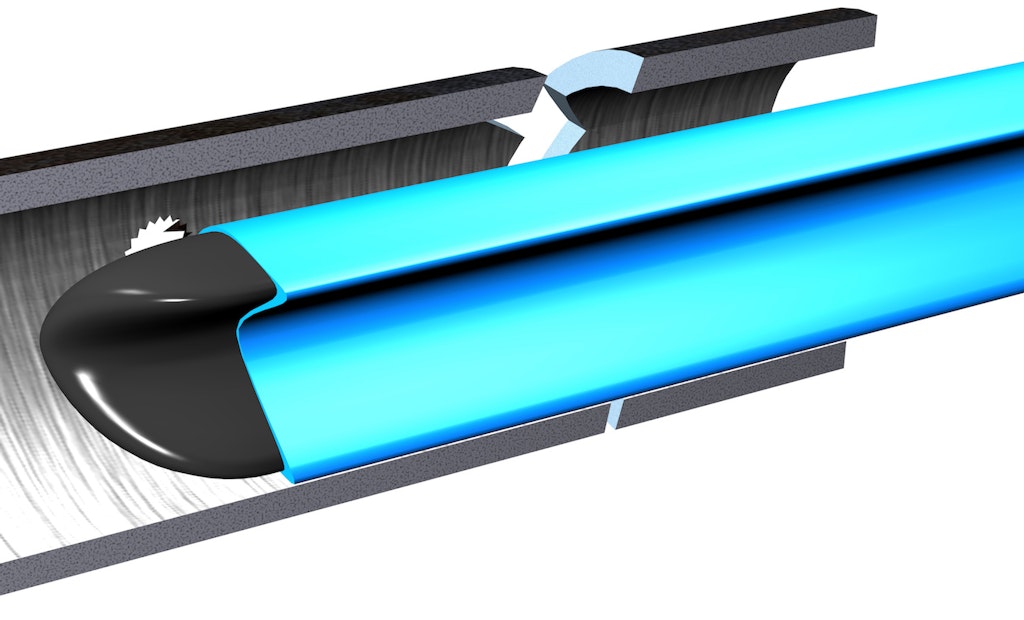

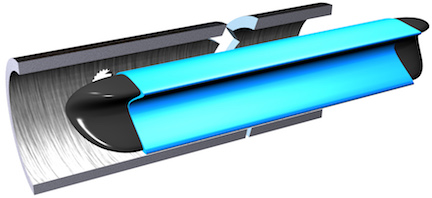

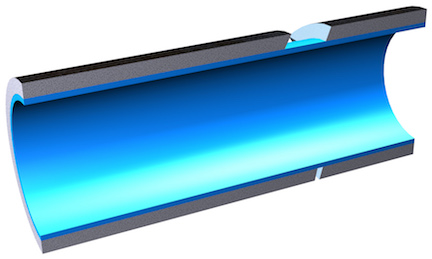

CIPP lining (Nu Drain) process

CIPP lining is a way to restore pipe damaged by corrosion, leaks or cracks from roots. It’s a four-step process and essentially is putting a pipe within a pipe. Lining is cost-efficient and less disruptive in comparison to replacing the entire system. Pipe lining also increases the life span of a piping system, preserves the building structure and landscape, and causes little to no destruction to the property.

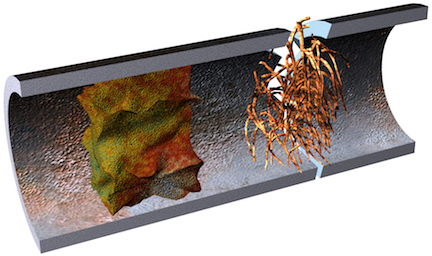

Installing a CIPP liner(s) begins with inspecting the condition of the pipe system with a CCTV camera. Any cracks, root infiltration, corrosive buildup or any problem areas are accurately mapped.

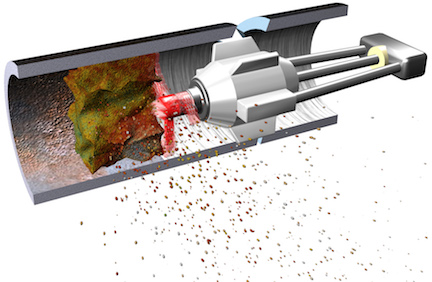

The internal pipe system is then cleaned of buildup and corrosion so that the liner will adhere to the inside walls of the host pipe.

After cleaning, the pipe system measurements are transferred to the lining material and the segment is built. This ensures the liner is accurately measured for installation. Once the liner is built to length a calibrated air pressure test ensures the liner will install property.

A two-part 100 percent solids epoxy resin is measured and thoroughly mixed. A calibrated roller is then used to saturate the felt liner, which is then folded and taped together. This reduces the profile of the repair segment and allows for ease of installation through small-diameter piping networks.

The epoxy-saturated liner is then pulled into place through an existing access point such as a water closet, roof vent or other access points already existing in the system. When the liner is in place, the technician is able to double check the placement of the repair and can make any last-minute adjustments, giving the installer complete control of the installation process.

Once in place, the bladder inside the liner is connected to hot water, compressed air or both in order for the saturated epoxy liner to exothermically cure.

Once cured the bladder is deflated and removed from the system. A final CCTV inspection takes place to ensure the liner was installed correctly. Nu Drain is the solution to solving and extending the useful life span of non-pressurized piping systems.

Visit the NuFlow Technologies Storefront