Interested in Cleaning?

Get Cleaning articles, news and videos right in your inbox! Sign up now.

Cleaning + Get AlertsEditor’s note: Cleaner Classroom is an online series focused on the fundamental functions of cleaning professionals and the basic tools used to clean, inspect and rehabilitate water, sewer and drainlines.

For pipeline cleaning professionals, fast and efficient waterjetting is essential to maximizing profitability and the return on investment for the jetter. Yet many contractors fail to optimize jetting performance because they don’t understand the basics of two critical components: nozzles and tips.

Without the correct nozzles, a water jetter is like a Ferrari without wheels — all revved up but incapable of delivering peak performance. Since you’re already in the know about the kinds of jetters available and which ones best suit your needs, it’s now time to explain the fundamentals of nozzles and tips.

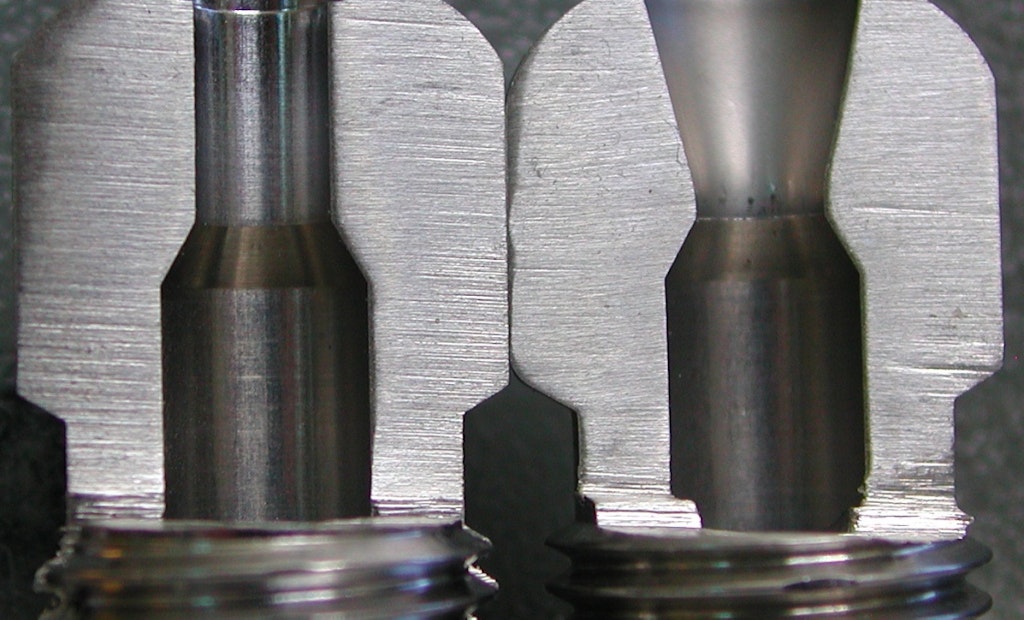

Because the terms often are used interchangeably in the industry, it’s helpful to first define what they are. Nozzles are rotary tools that go on the end of the jetter hose and deliver water. The tips are small, replaceable inserts that screw into holes in the nozzle; the tips create the high-pressure streams of water that not only propel the nozzle along pipelines, but also cut roots and scour sludge and scale from pipes, says Mike Bollinger, sales director of the sewer division at StoneAge, a leading manufacturer of these tools.

Water jetters typically come with nozzles and tips included. But more often than not, the contractor does not receive an in-depth explanation about how nozzles and tips work and how to use them effectively. As such, it’s up to contractors to do their homework and determine what’s suitable for their needs, Bollinger points out. (To learn more about the different tiers of nozzles, check out "Nozzle Knowledge: How to Pick the Right One").

“Typically, a contractor buys a jetter and they’re off and running,” he says. “Then six months later, they have to deal with issues such as pump maintenance and hose and nozzle wear. That’s why more education is necessary.”

For starters, tips are basically made from four different materials: stainless steel, carbide steel, ceramic and sapphire. Which one you should use depends on the work you do, Bollinger says. Sapphire tips, for example, are used predominantly for extremely high-pressure hydroblasting jobs (at 40,000 psi or more), such as cutting concrete, while stainless steel and carbide tips are most commonly used by municipal and commercial drain cleaners.

Carbide steel and ceramic tips are best for contractors who use dirty, unfiltered water that’s propelled at high flow rates below 20,000 psi. Stainless steel tips can better tolerate rough handling, and require the use of clean water (filtered to 25 microns or better) at pressures of less than 20,000 psi, he says.

“The water source determines what kind of tips you should buy,” Bollinger says. “If you typically use higher-quality, filtered water, stainless steel is a better jet for you. If you’re using poor-quality water, such as fire-suppression water or water from a cooling pond at a plant, a carbide or ceramic tip is better because they’re harder and won’t wear as fast. Carbide tips are made with binders that make it less vulnerable to the abrasive suspended elements and particles in poor-quality water.”

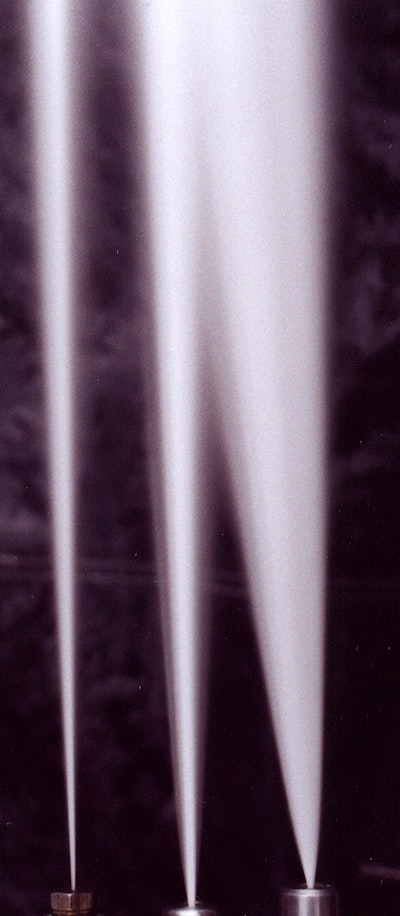

That brings up an important point: While it may seem hard to believe, a tip will eventually wear out because small particles in the water can actually erode its flow channel. This creates a fanned out stream of water, which is not nearly as effective as a tight, cohesive stream of water, Bollinger says.

The flow generated by your jetter’s water pump, combined with the size and length of the hose you’re using, will determine how many tips your nozzle should include. For a higher-volume jetter that operates at 3,000 psi at 80 gpm, you should consider a nozzle with four to six tips, because three tips isn’t enough to maximize the high water flow being generated. In a sense, it’s like trying to shoot shotgun shells through a bb gun. But for a cart-mounted portable jetter, on the other hand (say, 4,000 psi at 10 gpm), three tips will work just fine, he says.

“Optimally, you want to use as few a number of tips as possible,” Bollinger explains. “More isn’t always better. All rotary tools are designed to cover the entire interior surface of pipe, so you must have at least one forward tip and two out the sides to generate enough power to pull the tool away from the operator and move down the pipe.

“You can’t clean as effectively with just one tip, but too many tips divides the horsepower in the pump between them, and you lose power,” he continues. “So three to six tips (for a high-powered jetter) is most effective because it delivers the water with enough power to get the work done.”

Contractors also need to keep in mind that water pressure at the nozzle will decline as the length and inside diameter of a hose increases, which reduces cleaning capability. As such, it’s critical to select tips with the correct diameter to maximize cleaning efforts. (For a handy pressure-loss calculator, visit www.jetting.stoneagetools.com.)

“Across sewer cleaning and high-pressure jetting, miscalculating pressure loss is where we see most contractors go wrong,” Bollinger says. “The tips need to be sized correctly to manage your pressure loss. Too many contractors assume all they need is a pump, a hose and a nozzle.”

For example, a contractor who typically does jobs that require longer hose runs (say, 500 feet) with a 1/2-inch-diameter hose, and usually works at a pressure and flow of 4,000 psi at 10 gpm, will need to use one jet forward at .029-inch-diameter and two back at .047-inch-diameter. In this case, using tips with larger inside diameters — or that are badly worn — will prevent the technician from getting up to the desired operating level of 4,000 psi.

Moreover, if a contractor owns more than one water jetter and they’re made by different manufacturers, the nozzle tips are only interchangeable if the pumps’ pressure and flow are the same, he adds. “If two water jetters have different pressure and flow, you have to resize the tips to fit each water jetter,” Bollinger says.