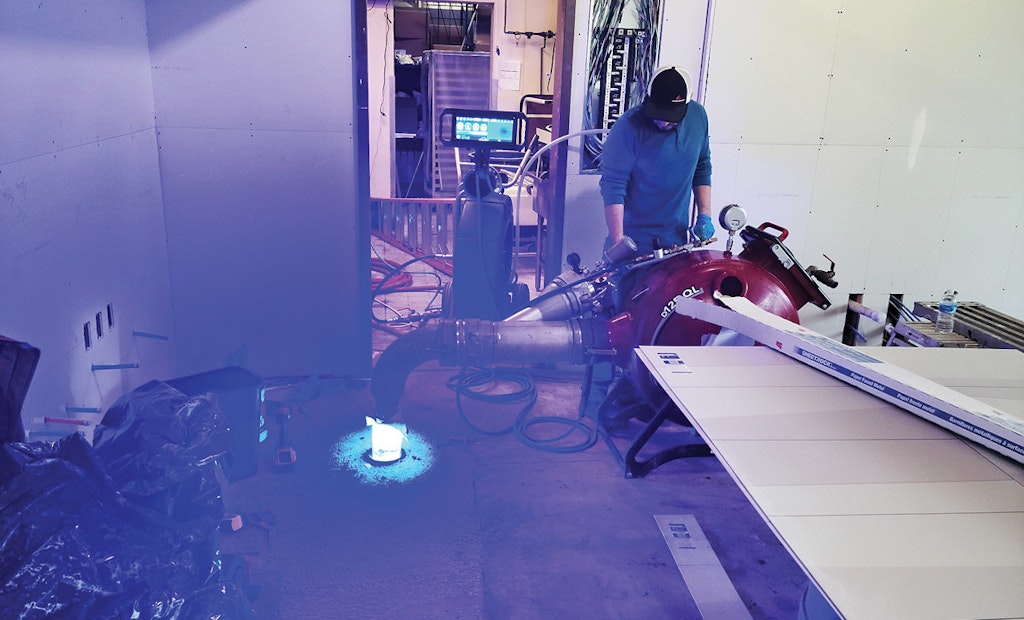

The HammerHead Bluelight LED system cures only under blue light, which means there’s no worry about resin curing in the drum. The system is also highly automated. Once the liner is in place, Schneider just monitors the system to make sure everything is progressing well.

Interested in Relining/Rehab?

Get Relining/Rehab articles, news and videos right in your inbox! Sign up now.

Relining/Rehab + Get AlertsMatt Porretta was ready to give up CIPP lining. It was frustrating, time consuming and discouraging.

Fortunately, he and his team found that the Bluelight LED CIPP system from HammerHead Trenchless relieved the pressure they once faced lining pipes.

“I had a really hard time inverting and installing liners,” says Porretta, owner of Underground Pipe Co. in Canandaigua, New York. “When you’re mixing resins and trying to get it in place in time before it starts cooking and getting hot — well, I don’t do well under pressure and lining wasn’t enjoyable for me. I was stressed out.”

After a handful of frustrating experiences with his previous lining equipment, Porretta was finished wasting his time, energy and money. “I had a job that I lost a 120-foot liner in the drum that I couldn’t get in in time,” he says. “That was a lightbulb moment; I knew I had to do something different.”

In another scenario, Porretta had lined a big job only to find out the prep work supposedly done before he arrived was not completed and he had to redo the lining. That situation could have been avoided using the Bluelight technology.

“After that, I stopped lining until I got the Bluelight,” Porretta says. He reached out to HammerHead and ordered their newest Bluelight LED CIPP lining system. “I pushed off all my jobs for a couple months until it was released and when I got it, we hit the ground running.”

Opening new avenues

Underground Pipe Co. has been busy since. “If I had to guess I’d say we’ve done about 70 jobs with the Bluelight since getting it around August,” Porretta says. “I tried to take some time off around Christmas but ended up working the whole time with emergency calls, and I’m not complaining. Business is great.”

The Bluelight LED curing system uses compressed air to invert the Bluelight liner into pipes from 3 to 10 inches. Once the liner is in place against the pipe walls, a control unit directs an LED light with live camera feed through the pipe to ensure there are no obstructions or flaws in the liner. The resin only cures under LED light in the blue light spectrum; so when the Bluelight LED is pulled back through the pipe, it cures the liner at rates up to 5 times faster than other methods.

The lining system really shines for Porretta and his team on the jobs where inverting is difficult. “It’s the jobs where I don’t want to dig the floor out and I can invert through a clean-out,” he says.

On one occasion at a local high school, it took almost five hours to get the liner out of the drum and invert. Though a challenge in its own sense, taking that time to do it right was possible because he didn’t have to worry about resin curing in the drum. It has taken out the time pressures of traditional curing methods.

Time saver

“The cure times are incredible. I can cure most of my shots in 45 minutes, and that’s to cure the entire drain or sewer line,” Porretta says. “I get a lot of calls for shorter shots like 15 to 20 feet and I can cure that with my Bluelight in 10 minutes. I’d say it’s at least twice as fast as using traditional methods.”

Along with quicker cure times, Underground Pipe Co. has not had to double back on jobs thanks to the built-in camera attachment on the LED light which allows a visual on anything potentially problematic before curing starts. “I have not had a single failed shot since we’ve got this thing,” Porretta says. “Honestly, I don’t know how you could fail unless you purposely make a decision to not care.”

The Bluelight features a large touchscreen interface where users can view pipes with the camera feature and can input specific job specs. After the information is programmed, the onboard computer sets and controls an automated pullback speed, removing the human error of pulling it back too fast or too slow.

Porretta has noticed significant time savings from less prep work and repair as well. “Pretty much all I do now are clean-out shots. I don’t break floor out anymore,” Porretta says. “If it takes an extra 20 or 30 minutes to invert, that’s fine. It’s still faster than breaking out concrete.”

His customers also like how quickly jobs are getting done as it means less downtime that they can’t use their sewers or drains. “I’d say a third of my jobs I would not be able to do without the HammerHead Bluelight,” he says. “I would not have the appropriate amount of work time.”

Standout service

Reliable customer service is something else Porretta is adamant about. The people behind the machine are just as important to him as the machine itself.

“We hadn’t even bought anything from HammerHead yet, but when we called and reached out the first time, a couple of their guys actually flew out to a job site we were on, helped us invert and shoot liner and they had no vested interested at that time,” Porretta says. “When I actually bought one, they had one of their guys come out and unbox it with us and train us on how to use it.”

That training made an easy transition for Porretta and his crew and gave them the confidence to start tackling jobs almost immediately after receiving the Bluelight. “Their trainers are ridiculously knowledgeable. They have been around it a long time so if you have an issue, these guys will know some way to help you get through it,” he says. “It’s about customer service for me, and I’ve never had a bad experience with HammerHead.”

It’s been almost a year now since Underground Pipe Co. has been lining with the Bluelight, something that for a while Porretta wasn’t sure he’d be doing anymore. This tool is something he would recommend to anyone who wants to start lining or is looking for a different method. “Lining became fun for me when I got the Bluelight system,” he says. “And it wasn’t fun for me before.”