Interested in Cleaning?

Get Cleaning articles, news and videos right in your inbox! Sign up now.

Cleaning + Get AlertsUntil now, there was not a governing standard applicable to a collections system after it was placed in service. Early sewers depended on infiltration and other forms of flushing to dilute sewage. This infiltration was originally seen as a benefit and was the primary method of “cleaning” the sewer. Factory-manufactured joints to eliminate infiltration weren’t a requested feature of clay pipe until the 1960s. Common practice was to clean pipe only when a backup made it necessary. Cleaning methods most commonly used through the mid-20th century were either mechanical tools (some form of rodding or bucket machines) or a rudimentary flushing procedure (including go-devils).

In December 2021, ASTM International published the first international standard ever to specify accepted practices for cleaning vitrified clay pipe in accordance with OSHA, Department of Transportation, CDC and Environmental Protection Agency standards (including capacity, management, operation & maintenance specifications). This industry-first standard establishes a requirement to return a cleaned pipe to at least 95% of its original design capacity.

ASTM C1920-21 Standard Practice for Cleaning of Vitrified Clay Sanitary Sewer Pipelines was developed and approved in accordance with ASTM’s consensus balloting procedures, including requiring 90% approval from the members of C04 Committee on Vitrified Clay Pipe, which consists of contractors, owners, engineers and pipe manufacturers.

In the first 118 years of ASTM standards for VCP, many technical standards were developed that covered all aspects of manufacturing, quality control, testing, installation, jointing, bearing strength, chemical resistance and field acceptance testing. Many of these standards were industry firsts and are still in use today.

Some pipe cleaners today, both municipal employees and contractors, consider a pipe clean once a hydro-jet nozzle has successfully traveled through the length of the pipe run. Cleaning by length traveled, without a set level of cleanliness, can result in significant levels of deposits, debris and FOG remaining within the pipe. In any pipe, the continuous presence of these materials can build up on the inside of pipe walls, solidify and coagulate with similar particles. The end result can be a partial or complete blockage of a pipeline that could lead to a sanitary sewer overflow.

A governing standard was needed in part to establish a benchmark defining a clean pipe, and in part because of evolving EPA directives. The introduction of many newer and more powerful cleaning tools also made the development of a standard necessary. To address these concerns, Section 7.1 of the new standard plainly states, “The standard operational procedure of high-velocity cleaning a vitrified clay pipe is to safely remove all obstructions and deposits from the pipeline and restore the pipe to a minimum of 95% of operational design capacity.”

“Returning pipe to this level of performance is the primary method for ensuring that an installed pipeline will perform as designed for the duration of its service life,” according to Kent Carlson of the National Clay Pipe Institute. “We demonstrated that a return to 95% of operational capacity significantly reduced overflows while I was with the city of Los Angeles. That practice has saved the city tens of millions of dollars over the past several years.”

The standard also clearly defines the differences between several types of nozzles:

- Static

- Cleaning

- Flushing

- Dredging

- Stoppage

- Rotational

- Governed rotational

- Free spinning rotational

Mechanical and hydromechanical tools are also specifically permitted under this standard, including the following:

- Hydraulic cutters

- Tap cutters

- Chain/cable flails

- Rodders

- Power rodders

- Bucket cleaning machines

The nature of the tools and the environment in which wastewater professionals operate make safety a necessary part of the new standard. Worker safety is a focus, including defining the activities required to mitigate hazards during the sewer cleaning process. Safety standards from OSHA, CDC, DOT and EPA are an important part of the procedures established in C1920. The standard reinforces the personal responsibility of each employee and employer on any job site.

“While the procedures and the 95% minimum can be applied to any pipe material, some of the tools are not appropriate for flexible pipe materials,” Carlson says.

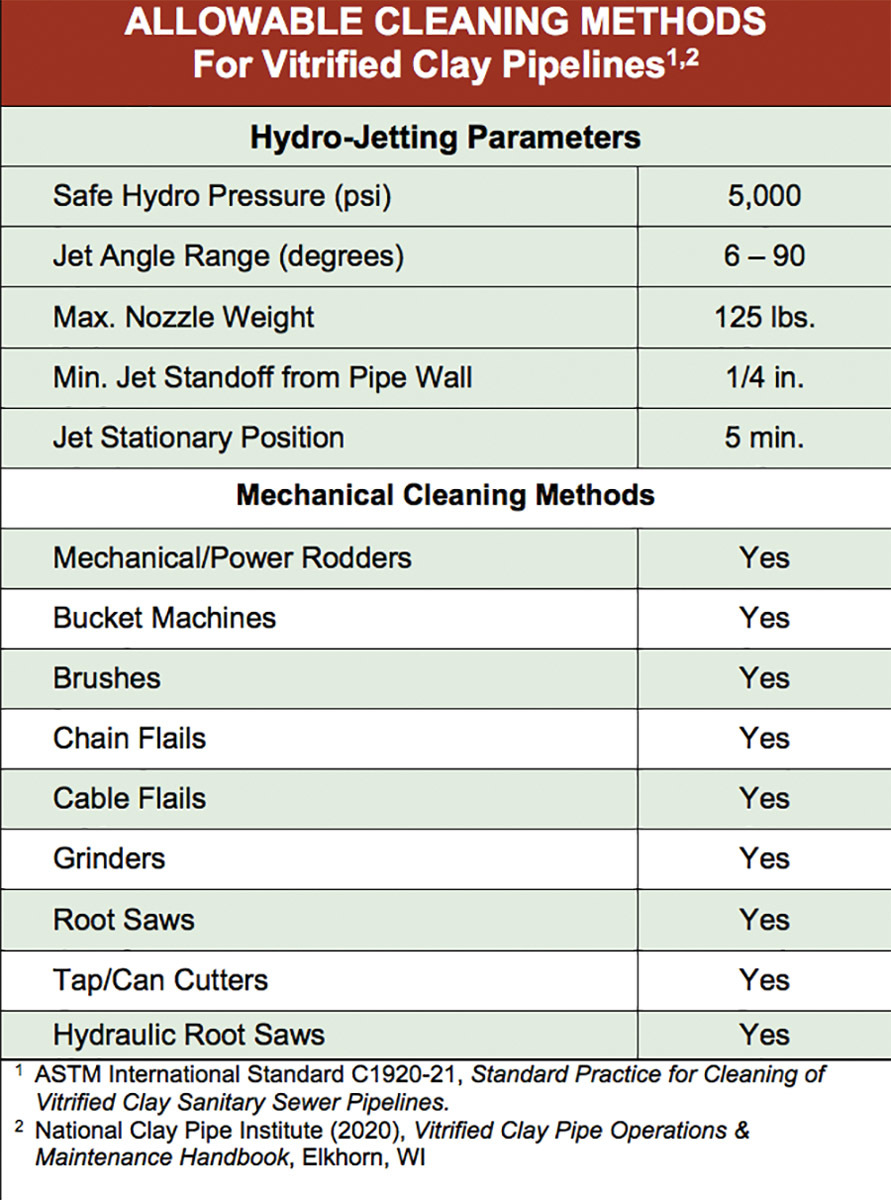

Because of the different material properties of pipe, the specific jetting pressures and mechanical tools in this standard can only be used for VCP. While the basic procedures are sound for any pipe cleaning operation, other pipe materials require greater care. They have lower jetting limits and do not permit mechanical cleaning methods. For example, the term “high-pressure waterjetting” in the VCP standard specifically refers to pressures of 2,000 psi and above. This is beyond the recommended pressure for other pipe materials. Check with your pipe manufacturer to determine the appropriate limitations for other pipe materials.

While the standard was still in review by the committee, some municipalities began to adopt this new standard as the benchmark for their cleaning contracts. The new standard creates a reasonable, uniform and consistent specification for any cleaning plan.

Scheduled cleaning reduces sanitary sewer overflows and increases the service life of any sewer while ensuring that design capacity is maintained. With the acceptance of this new standard, VCP became the only pipe material that has specific ASTM guidelines for cleaning pipe as part of the plan for long-term operation and maintenance of pipelines.

The new standard (ASTM C1920-21) is available from ASTM International (www.astm.org/c1920-21.html).