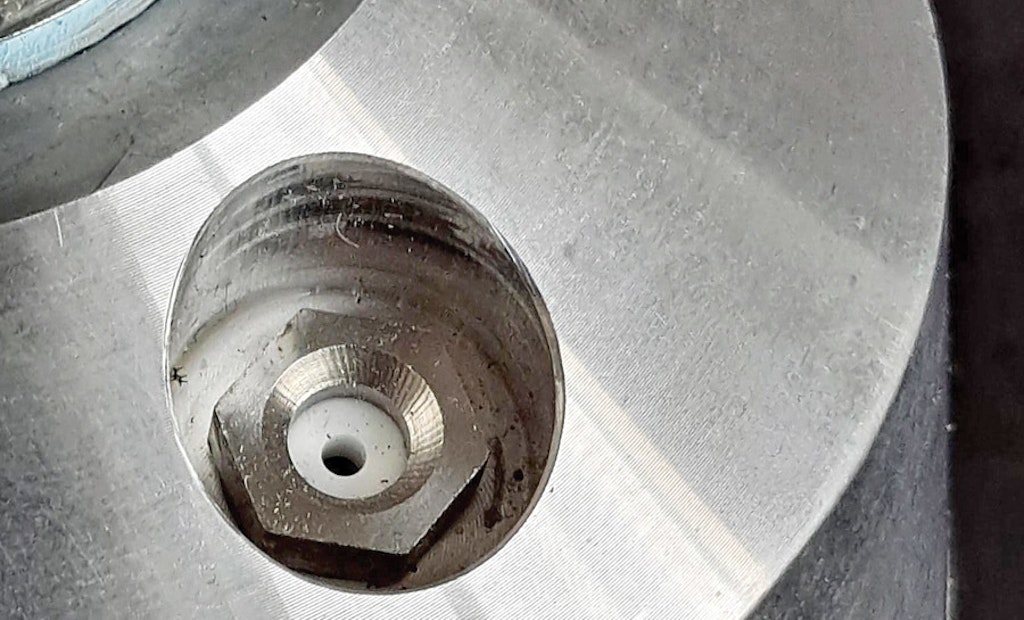

Jet angles, orifice size and cohesive flow play are important factors in nozzle efficiency. (Photos courtesy of NCPI)

Interested in Cleaning?

Get Cleaning articles, news and videos right in your inbox! Sign up now.

Cleaning + Get AlertsThe nozzle you select makes a big impact during sewer cleaning. Specifically, the selection of cleaning nozzles is a critical element of hydro-flushing.

In the last two decades, advancements in nozzle jets have changed the performance criteria for sewer nozzles. Jets now are far more efficient in delivering more thrust when set at a higher angle to the axis of the pipe. The old-school requirement for lower jetting angles to speed progress has gone out with the debris.

With that said, nozzle selection with higher jet angles and larger orifice jets can be obtained with the ability to still clean efficiently at a rate of 10-20 feet per minute. This cleaning speed can be achieved while reaching the goal of restoring a line to 95% of operational capacity.

To reduce sanitary sewer overflows and the frequency of cleaning required, a sewer pipe should be cleaned to a minimum 95% of its operational capacity (measured at the pipe’s internal diameter). To accomplish this, the selection of a sewer cleaning nozzle (rotational, static or specialized) must be based on three important factors:

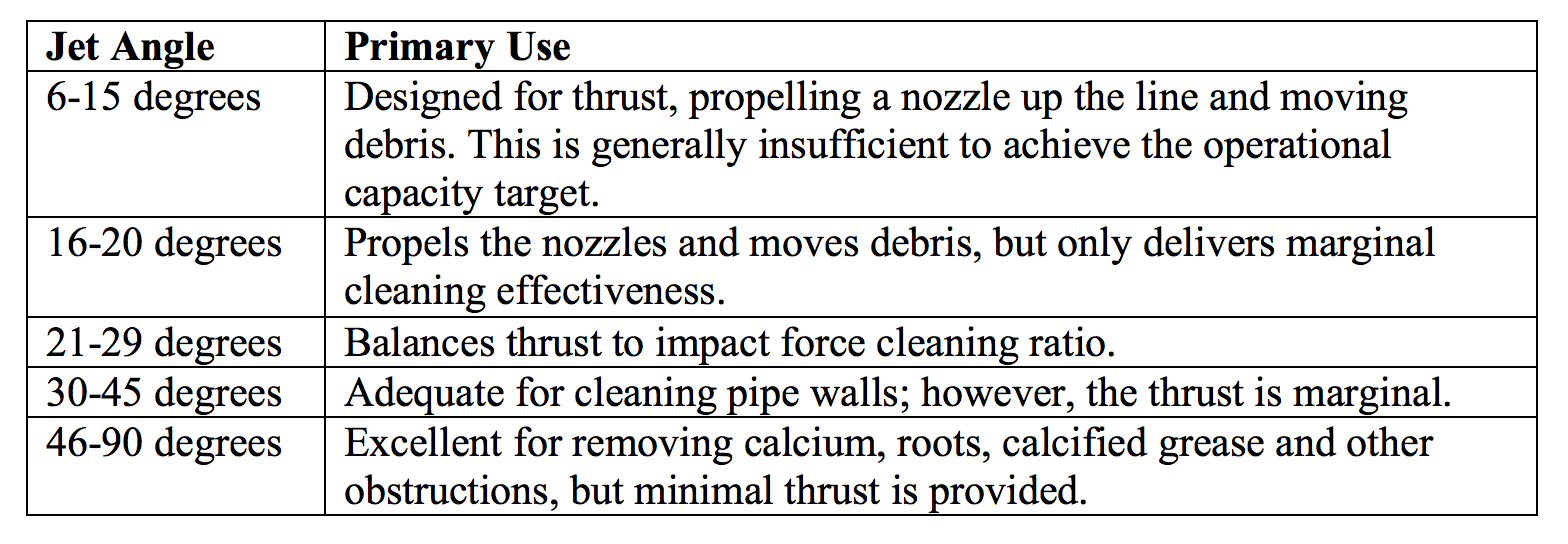

1. Angle of the jet from the axis of the pipe.*

2. The quality of the jet and cohesive stream flow.*

High-quality jets or inserts have a cohesive jet stream. Cohesive jet streams travel farther through the air before breaking into droplets and their streams carry energy for a longer distance. A non-cohesive stream can be caused by drilled jets and low-quality inserts.

3. The ability of the nozzle to deliver the proper gpm and psi to the pipe.*

Larger jets hit harder and last longer. Whether it’s a rotational or static jet nozzle, a low number of larger orifice jet inserts will ensure greater force and cleaning strength across the pipe circumference. A higher number of inserts with smaller orifices will enable more spreading of the water while the impact force is weaker across the circumference of the pipe.

* Consult pipe manufacturers’ specifications for cleaning methods including jetting angles, gpm, psi and stationary position limitations.

Proper adherence to engineering, installation and maintenance standards is important to realize the best, long-term service from any pipe. As an example, the longest warranty in the sanitary sewer pipe industry is offered by vitrified clay pipe, which carries a 100-year warranty. Keeping the pipelines clean over the entire life cycle is critical to maintaining operational capacity, eliminating inflow and infiltration, and preventing SSOs.

The maintenance of a sewer is not only an integral part of its operations, it is also the most impactful factor in the longevity of the sewer after it is properly installed. Many cities employing a robust cleaning program have operational VCP sewers that are well over 100 years old.

As maintenance and operations professionals consider nozzle options, they should also not be overly reliant on the tier rating system. This system rates a nozzle 1, 2 or 3 (with 3 being the top tier). A common misconception in the sewer world is that this system is based on the “cleaning effectiveness” of a nozzle.

Keep in mind that “cleaning effectiveness” is based on what the water streams do after they leave the nozzle. The meaning of “clean” in the sanitary sewer world is to remove something unwanted.

A recent industry poll asked the question: What determines whether a sewer nozzle is considered a Tier 1, 2 or 3? It was a multiple-choice survey with four possible answers. The survey respondents’ answers had the following distribution:

-Cost of the nozzle: 2%

-The type of nozzle: 19%

-Nozzle’s cleaning effectiveness: 31%

-None of the above: 48%

A surprising 31% of respondents believe that the tier rating system represents the “nozzle’s cleaning effectiveness” and 19% believe that it represents “the type of nozzle.” Less than half selected the appropriate answer: “None of the above.” This distribution is just one demonstration of how common misconceptions are regarding this rating system.

The system’s main rating criteria is based on the flow of water through the nozzle coupled with the internal and external design of the nozzle and not by the cleaning effectiveness of the nozzle at the pipe wall. The most efficient flow of water through the nozzle garners a higher rating. In this system, the flow of the water through the nozzle is important, but the jet and orifice designs deliver the water stream to the inside of the pipe wall.

Because of the internal and external design criteria of the tier rating system, rotating nozzles, sewer floor nozzles, stoppage nozzles and hydromechanical tools are not rated by this system.

The tier system also quantifies a nozzle’s cleaning based on footage cleaned (speed) but not the resulting cleanliness and restored operational capacity (effectiveness).

Most sewer cleaning crews utilize several types of nozzles to handle a range of issues found while cleaning. Selection of these nozzles requires researching different nozzle manufacturers and their designs while understanding the limitations dictated by the pipe material and condition. Refer to the information that should be provided by the pipe manufacturers to ensure a clear understanding of these limitations.

The National Clay Pipe Institute recommends benchmarking nozzles through actual cleaning processes to assess how the nozzle operates within a given system, under pressure. The ultimate test is if it performs to the user’s standards. NCPI offers a training workshop that includes a review of best practices for maintenance and proper VCP cleaning techniques. This particular workshop is built on my more than 30 years’ experience in the Wastewater Collection Systems Division for the City of Los Angeles and 40 years of designing and manufacturing nozzles. This maintenance workshop qualifies for professional development hours and can include an evaluation of a municipality’s cleaning program.

Always remember that a $500,000 sewer truck is only as good as the cleaning effectiveness of the nozzle at the end of its hose and how that system, in combination, delivers to the inside of the pipe wall.

About the author

Kent Carlson is vice president of the National Clay Pipe Institute (www.ncpi.org). Before joining NCPI, he retired as the operations manager for the City of Los Angeles Wastewater Collection Systems Division.