Inspecting chemical pipelines for defects is a risky business. For that reason, Specialized Maintenance Services Inc. (SMS) in Pasadena, Texas (a Carylon Company), relies heavily on its fleet of seven EX-Zone Approved pipeline

inspection cameras made by Pearpoint/SPX.

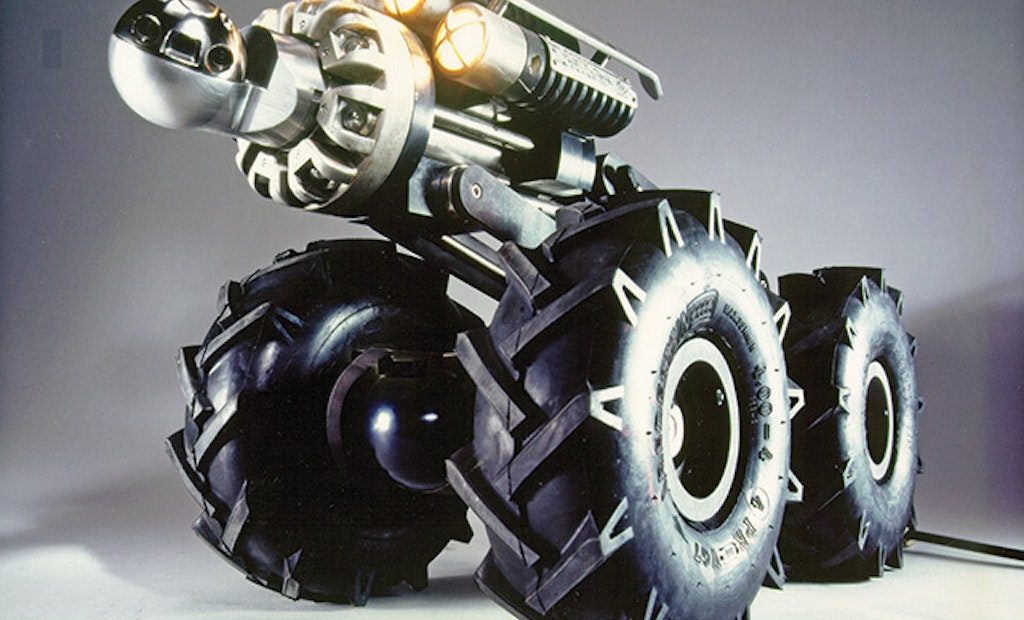

The cameras are made mostly of brass and are equipped with Kevlar-coated cables that are sealed on the ends. That enables the tractor-mounted cameras to safely inspect hazardous environments without creating explosion-igniting sparks, says Darrell Martin, president of SMS, which cleans industrial pipelines and tanks and also provides hydroexcavating services.

"It's extremely dangerous work," Martin explains. "When we open a manhole, we first do an air reading to detect the presence of volatile organic compounds (VOCs). We also wear Nomex (flame retardant) suits. These machines have to be explosion proof. If we're going down the line and we hit something and create a spark, and there still are VOCs in the line, there's potential it could explode."

Customers require SMS camera operators to obtain safe-operation certification from the manufacturer, Martin adds.

SMS bought its first Pearpoint inspection camera and camera van about eight years ago. Two factors drove the decision: the company's location on the Gulf Coast of Texas, amid a region dotted by hundreds of chemical plants, and federal clean-air regulations that required petroleum refineries to inspect pipelines to ensure they're not allowing VOCs to leak out.

"Our location is unique," Martin points out. "We're in southeast Texas, on the Gulf Coast, and there are about 400 chemical plants between Corpus Christi and Lake Charles, La., so we're in the middle of a potentially huge market. We're not some wonder child down here with these – we just happened to be in the right place and have been able to market this service and keep the equipment working."

After cleaning chemical lines with either water, various kinds of soaps or neutralizing agents (depending on what the pipelines carry), camera crews

inspect the lines, looking for defects that might allow infiltration and exfiltration of VOCs. If the operator spots a defect, he stops the camera and photographs it, then continues the inspection. When completed, SMS provides the customer with a DVD of the inspection, along with pictures and a bound report, Martin says.

The Pearpoint P455 cameras are mounted on P448 steerable tractors;

together, they cost about $85,000. That cost rises to about $150,000 with a camera van and all the other accessories included. While that's a significant investment, it's also a barrier to market entry for would-be competitors. As an expert in the field, SMS develops enough business volume to keep them busy and generating revenue, Martin notes.

"We probably have one of the largest fleets of these inspection cameras in North America," he explains. "If you're not committed to this, and don't have the steady work, the cost is definitely prohibitive. You can't make that kind of investment and have them sit.

"The upside is that they've opened up new markets to us, and they are very profitable from a billing standpoint," he continues. "They're our most profitable line of business, representing a substantial percentage of our total volume ... if you're capable of keeping them working, they'll eventually pay

for themselves."