Interested in Education/Training?

Get Education/Training articles, news and videos right in your inbox! Sign up now.

Education/Training + Get AlertsSewer contractors understand the need to protect themselves with sensitive portable monitors that detect hazardous gases.

But the wealth of options on the market can make selection complicated. Should you buy meters that detect the one gas your people are most likely to encounter? Or multi-gas meters that can detect several gases at once?

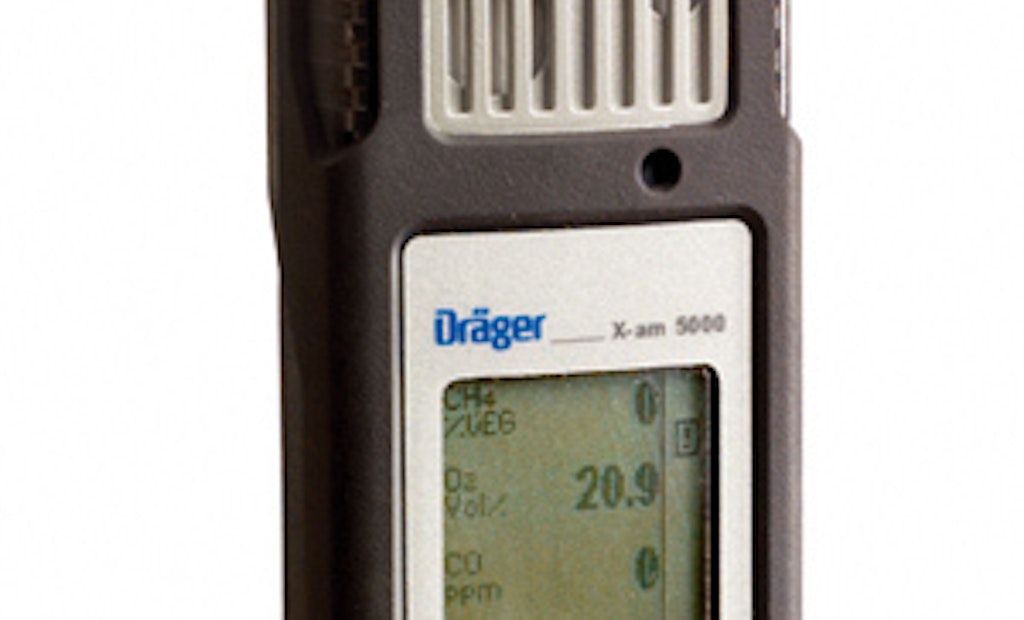

When outfitting an entire crew with similar protection, cost becomes an important factor. “In most cases, sewer contractors know what gases they’re likely to encounter,” says Rick Wanek, industry market manager, portable instruments, with Dräger Safety Inc. (Draeger). “If they’re likely to run into anything unusual, like chlorine used to treat wastewater, they’re usually informed of that type of gas hazard before they get to the site.”

While there’s no hard-and-fast rule, most jurisdictions require workers to use meters approved by Underwriters Laboratories or the Canadian Standards Association. Although Wanek says counterfeit equipment occasionally reaches the market, the guilty parties are quickly eliminated. “In order to sell, they have to advertise, and organizations like UL are quick to defend their trademark,” he says.

Rigorous approvals

Detectors approved by the Mine Safety and Health Administration (MSHA) are more costly than those approved for sewers – not because they necessarily provide more protection, but because the mine sector represents a smaller market with a much more elaborate and costly testing regimen.

“Sewer contractors provide a much larger market, so testing costs are distributed across far more units,” says Wanek. “Sewer contractors wouldn’t get extra protection for their needs by buying a detector approved for mine use.”

The meters use a number of technologies appropriate to each gas they’re designed to detect. A multi-gas meter may use multiple methods to detect a range of gases. For example, infrared sensors detect gas concentrations by shining infrared light through the sample. Electrochemical sensors read the electric currents generated by the interaction of specific chemicals and a target gas. More complex catalytic sensors ignite small samples of gases such as methane and measure the resistance between two filaments coated with precious metals.

Standard gases

“Sewer contractors generally favor meters that read the four standard gases,” says Wanek. “In a sewer setting, you would at least want to detect methane, oxygen, hydrogen sulfide and carbon monoxide.”

Why oxygen? Because meters that detect methane do so through electronic combustion of microscopic methane samples, and combustion requires oxygen.

Occasionally, contractors may work in confined spaces containing other gases, such as chlorine or hydrogen peroxide used in a water treatment plant. “Sometimes an accidental industrial spill will see an additional chemical accidentally released into the sewer,” Wanek says.

“Typically, the contractor will be warned about this beforehand. At that point, it may be more economical to buy additional single-gas meters to deal with the specific problems in the situation in which they’re working. Generally, workers are reluctant to carry two meters, but that may be the least expensive way to go on a case-by-case basis.”

Gas detectors are also rated according to Ingress Protection (IP), a two-digit number. The first digit represents dust protection, on a scale of 0 (or X) to 6, while the second represents water protection, on a scale of 0 (or X) to 8. A unit rated IP 67 would be dustproof and highly water resistant, submersible for brief periods at shallow depths.

Getting smaller

Wanek notes portable monitors are getting smaller. His company’s smallest portable meter measures 3 inches long by 2.5 inches wide and a half-inch thick. The larger ones measure about 2 by 6 inches and weigh 6 or 7 ounces.

“The meters could actually be much smaller, but we need to keep some real estate open for the display and the necessary labels that accompany the meters,” Wanek says.

Meters alert users to threshold levels of gas by sounding an alarm – either a vibration or a sound. Some provide a two-alarm system: a low-level alarm that indicates the gas levels are creeping toward the threshold, and a secondary alarm that warns the user that the threshold is being passed. “At that point, you simply evacuate,” says Wanek.

Acceptable thresholds for various gases can change from country to country and can be programmed into the instruments by the manufacturer or the user. In the U.S., meters are programmed to defaults set by OSHA Confined Space Entry regulations, CFR 1910.146. In Canada, they’re set under regulations determined by each province.

“The user can change those presets or change the type of alarms with a software interface,” says Wanek. “That software is necessarily password protected, because you don’t want the average worker to change those settings. A beeping unit is annoying because it’s meant to annoy you and alert you to a problem. You don’t want anyone to hit a snooze button in a critical situation. If the threshold is set low, you may occasionally get a false alarm, but better to have some false alarms and know the meter is working.”

Tube testers

For contractors who only occasionally work where gases beyond the traditional four are present, alternative devices can be used. Dräger-tubes, for example, are glass ampoules containing reagents that can detect specific gases in various environments.

“You pump the surrounding atmosphere through the tubes to determine peak concentrations,” says Wanek. “However, they’re best used in limited areas. Carrying a portable gas meter is essentially like carrying a movie camera running continuously, while using the tubes is more like taking a snapshot of a particular limited environment, such as in sewers, shafts, tanks or other confined spaces.

“We often find tubes used to measure concentrations of specific toxic or carcinogenic gases, such as benzene, that are associated with a specific work site. We’ve had some sewer contractors using tubes to detect benzene that had leached into the surrounding soil.”

Another solution for occasional gas encounters is a chip system – a more advanced version of tubes in which a portable unit can be outfitted with a choice of 55 different gas-specific chips. This system also provides a snapshot of gas concentrations.

Sophisticated operation

While meter technology continues to advance, the basic measurement techniques remain largely the same. “The most dramatic change is in the microprocessors used to analyze the reading,” says Wanek. “For example, if you can be exposed to 50 ppm of a certain gas each day, and 60 ppm for a very short time, the microprocessor can calculate what is considered an acceptable exposure for the day through time-weighted averages.”

Contractors want value for their money and prefer to hang onto their meters for as long as they can. Typically, a portable meter is good for at least five years, Wanek says. Proper maintenance can make sure the units function effectively for as long as possible.

Units should be cleaned every few months to keep the display clear, and permanent filters should be cleaned as the manufacturer recommends to ensure free flow of sample atmospheres. Removable filters should be replaced if dirty. “If you drop the meter into the muck or into a pool of wastewater, clean it immediately,” says Wanek.

The meters should also be “bump-tested” each day by exposing them to a set sample of gas at a pre-determined concentration. The bump-testing kits act as mini-calibration tests to ensure the unit is reading properly.

“If you’re getting low response, or no response, you should check the filters,” says Wanek. “If the problem persists, the unit shouldn’t be used in the field.”

Portable units are powered by batteries. While they can run on alkaline batteries, Wanek says it’s often simpler to use rechargeable batteries, which can be gang-charged each night to maximum power. Alkalines need to be swapped out often to make sure they cover the entire workday.

Batteries should never be changed in a confined space, since there is a slight chance battery removal could cause a spark and ignite flammable gases.

Final word

A good portable gas detector is no substitute for safe work practices. “If you’re entering a confined space, it’s not something you should ever do alone,” Wanek says. “The detector will alert you to the hazard, but regulations dictate that you need a spotter to help get you out of there if there’s any communication indicating trouble.”