Interested in Cleaning?

Get Cleaning articles, news and videos right in your inbox! Sign up now.

Cleaning + Get Alerts“I built a heater to cure my liner, but it doesn’t seem to speed up the process as much as I’d hoped. Does a heater really help the curing process, and if so, what’s wrong?”

Many of you have installed instantaneous water heaters, and while there are pressure and volume issues that differ among manufacturers, the issue we’re talking about here has to do with the volume and speed of the water or steam going through the calibration or liner tube. We are going to look at turbulent flow versus laminar flow and how it plays into the curing process.

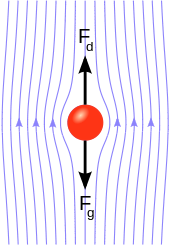

I looked up the definition of laminar flow in the dictionary and decided that the explanation was over my head. So I decided to illustrate laminar flow instead:

You will notice that the flow travels along a column and that the columns don’t cross each other. In other words, the flow on the inside doesn’t come in contact with the columns on the outside of the flow.

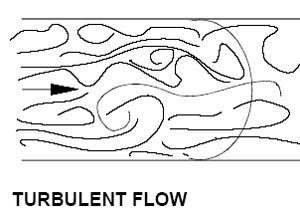

In looking at turbulent flow, the dictionary definition says, “that it is a flow regime characterized by chaotic property changes.” Again, best to go back to the drawing board. The picture below shows what turbulent flow looks like:

As this picture demonstrates, the flow doesn’t stay in the columns as shown in the picture depicting laminar flow. Instead, it tumbles and turns in the pipe.

So how does this apply to you and lateral lining? Many of you use or are thinking of using heat to cure your lines in order to speed up the process. To effectively get a heat source, either water or steam, to cure the liner in a shortened amount time, you need turbulent flow in the pipe.

Some of you have built your own heaters, which is fine, but you need to think about the mechanics of recirculating the heat you are generating to get to a turbulent flow state. If you are relying on gravity flow or flow with a pump or air compressor that is too small, you won’t move your water or steam at a fast enough pace to make it turbulent. Imagine sending your heated water or steam down a hose or tube to the end of the liner where it is dumped into the pipe. If you don’t have enough pump or air capacity to push the water or steam, it will exit and slowly return to the pump to be recirculated again, or in the case of steam, dumped to the atmosphere.

There are two things to consider: One is pump or air capacity and the other is the delivery hose size to get the water or steam from the pump to the far end of the line. A heating device that has a big pump pushing water or steam down a very small hose will create laminar flow. If the hose size that you’ve used for 100-foot shots is used to cure a 300-foot liner, you may find that what could produce turbulent flow at 100 feet delivers laminar flow at 300 feet. The same with the pump or air compressor. A pump or compressor sized for 100 feet may not be big enough to cure a 300-foot liner.

I had a call once from a customer who was exactly in this situation. He had a 250-foot-long 6-inch liner he was trying to cure with his boiler. He’d been at it for three hours and it still wasn’t cured. His boiler was cycling just as it would if the return water were warm enough to cause it to cycle, but the liner wasn’t being cured. In calculating what he was using, his heater was big enough, but both the 1/2-inch PEX pipe he was using and the pump were too small to maintain turbulent flow.

As you look toward your planning, consider your heat source size, pump or air source, and delivery hose sizes before you build a system so that you can be sure it will be viable for curing liners. And hopefully this will explain why sometimes your heating efforts are taking longer than expected.

About the author

John Heisler is the owner of Pipe Lining Supply and Quik-Lining Systems Inc. He has 20 years of experience in the CIPP lining industry and over 40 years in the underground construction industry.