Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

Inspection + Get AlertsTrenchless pipeline rehabilitation has come a long way in the years since its development. Pipe bursting and horizontal directional drilling are proven trenchless methods for renewing aging and deteriorated pipes. Rehabilitating storm drains, sanitary sewers and pipelines requires the best tools to complete jobs quickly and cost-effectively. Here we take a look at some solutions used to expose entry points and install new pipe and help you meet the demands of these specialty trades.

As a cost-effective method for pipe rehabilitation and underground infrastructure installation, trenchless technology has become the accepted option in more and more rehabilitation projects across the nation. It also means there are more products to consider when expanding or upgrading your service offerings to include pipe bursting or horizontal directional drilling.

Barney Allen Jr., owner of Allen’s Electrical & Plumbing in Savannah, Ga., relies on pipe bursting to keep customers happy, citing a recent residential job that included a labyrinth of walkways. “To dig and replace would have meant tearing up everything,” he says. “There was old Orangeburg pipe, and we used pipe bursting and didn’t have to tear up anything in that yard. That was a very excited and happy customer. It was an example we could point to in promoting the equipment.”

Whether you’re installing underground infrastructure such as power cable conduits and water or sewer lines or you’re looking for an alternative to open-cut trenching, directional drilling and pipe bursting are your best bet.

Pneumatic hammers and horizontal directional drilling tools available in today’s market streamline trenchless work and improve overall productivity. When traditional excavation is not an option, check out these directional boring tools to outfit your pipe rehabilitation operation:

- The 34-inch pneumatic pipe-ramming hammer from HammerHead Trenchless Equipment can install casing 48 to 180 inches in diameter in drainage culvert and washover applications. It also can be used for pipe assist or pipe extraction, guided pilot bore ramming and horizontal directional drilling.

- Designed for the underground utility contractor, the JT25 HDD from Ditch Witch offers 27,000 pounds of thrust and pullback, a rotational drive with 4,000 ft-lbs of torque and quiet drill operation. It is ideal for installing utility pipe and cables of up to 12 inches in diameter at lengths of up to 500 feet. It features a 130 hp Tier 4i Cummins diesel engine.

- Directional drilling pipe from Underground Tools Inc. fits all drill rig sizes from mini through maxi. It is made from high-quality materials, with consideration given to precise threaded connections. Integral forged drill pipe and forged/inertia-welded pipe are available.

- The D9x13 S3 Navigator horizontal directional drill from Vermeer has a small footprint that makes it ideal for installation projects in congested urban areas. It has a 44 hp Kubota Tier 4 Final engine, delivering 9,000 pounds of thrust/pullback and 1,300 ft-lbs of rotational torque.

Pipe bursting offers a viable option that causes very minimal disruption in customers’ yards or businesses. As a specialty trade, pipe bursting requires unique tools and equipment to meet the needs of customers and utilities that require less downtime and fewer disruptions to land and infrastructure.

Ryan Peterson, owner of Express Plumbing in Sacramento, Calif., relies on pipe bursting to meet the growing demands of clients who want jobs done quickly and who no longer want their lawns torn up. “Pipe bursting was the first expanded service in 2004 because the technology was faster and we didn’t have to dig,” he says.

If you’re considering expanding your menu of services to include pipe bursting, take a look at these tools:

- The Model PD-33 pipe bursting machine from Pow-r Mole Sales has a 24-inch stroke. Its nonslip cylinder-activated jaws prevent cable damage, while developing 60,000 pounds of pulling force at a rate of 6 feet per minute. It offers a cost-effective alternative to open-cut by reducing excavation up to 85 percent, and can burst cast-iron, concrete, HDPE, asbestos cement, PVC, ductile iron, Orangeburg and clay pipe from 2 to 6 inches.

- The Model 7000 pipe bursting puller from Poweram replaces existing utilities by pulling pipe splitting and/or bursting tools through the old pipe and pulling a new pipe into the same space. The new pipe can be the same size or larger than the old pipe. With over 118,000 pounds of pulling force, it can split or burst up to 12-inch pipe and pull back up to 16-inch pipe in most soil conditions.

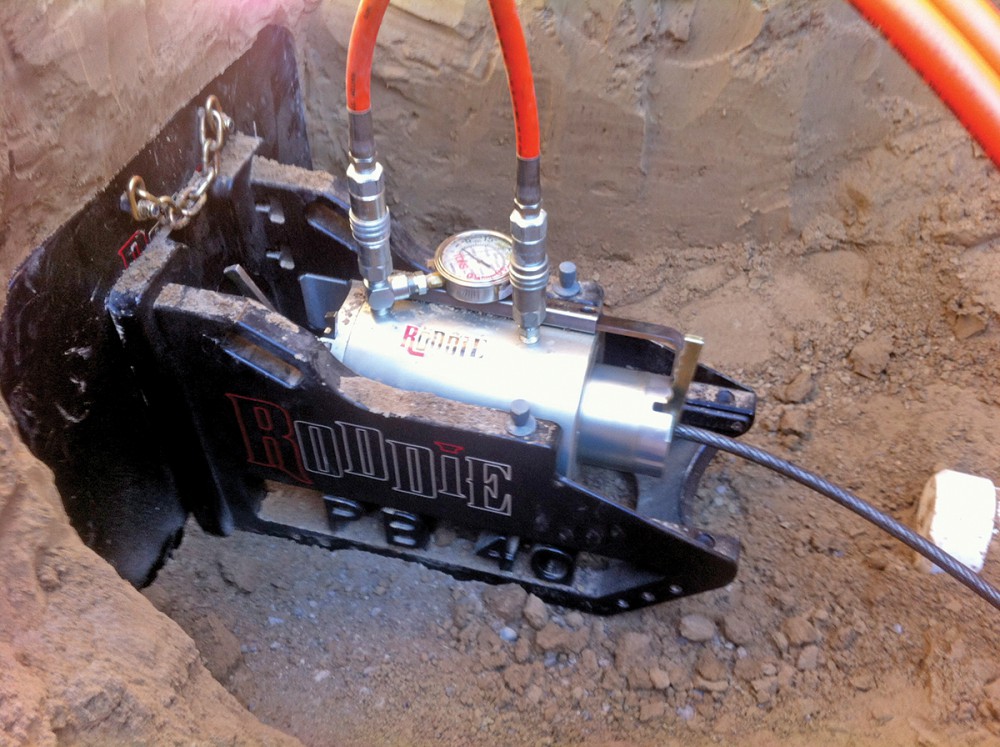

- The lightweight lateral pipe bursting machine from RODDIE Inc. slides apart into two components of 50 and 60 pounds that can be lowered and reassembled by hand in the excavated pulling pit. In most cases this machine is powered and operated by a mini-excavator or bobcat tractor.

- The UnderTaker pipe bursting system from Spartan Tool will replace existing sewer laterals with new, seamless, high-flow HDPE pipe from 2 to 6 inches in diameter. The system sets up quickly, without any tools, and handles up to three 45-degree bends in the existing pipe.

- The ergonomic Hi-Flow 13HP hydraulic pump from TRIC Tools delivers 4 gpm up to 5,000 psi, measures 28 by 27 by 26 inches, and weighs about 280 pounds wet. Ideally matched with the company’s X30 lateral bursting system, it also features an onboard pressure gauge, hour meter, folding transport handle and pick-point for loading/unloading, plus removable hoses and heavy-duty pendant control cable.

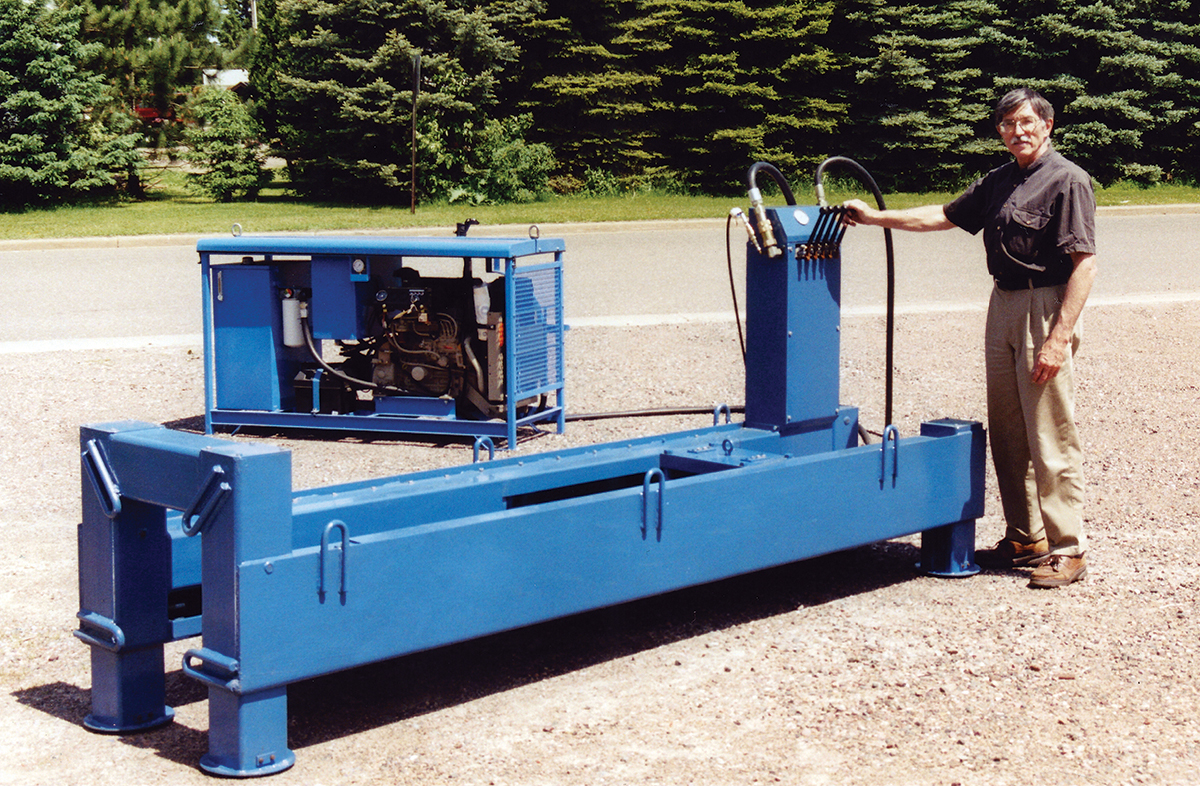

- The TT Technologies 3-ton Grundowinch hydrostatic constant-tension winch is suited for underground utility applications including pipe bursting, underground cable pulling, sliplining, pipe pulling and swage lining. It has protective cable storage and is available with an air-cooled diesel or gas engine, as well as an adjustable boom.

For complete product listing and manufacturer contact information, visit www.cleaner.com/editorial/2014/04/pipe_bursting_methods_and_projects3.