Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

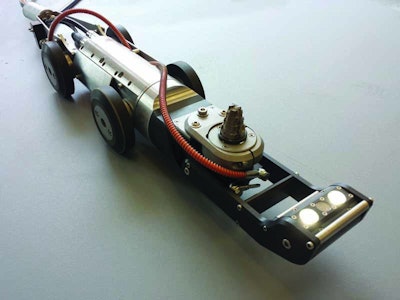

Inspection + Get AlertsThe modular SR-SERIES multifunctional sewer rehabilitation system from ID-TEC (Innovation Development Technology) is available as a portable unit or vehicle-installed system.

Both feature a base robot with twist-and-lock equipment for inspecting, root control, high-pressure precision jetting, packer/carrier placement, lateral reinstatement, and calcium and concrete removal.

The portable system includes a high-pressure water pump, cable reel and CP3D suitcase control unit with 10.8-inch tablet and two six-axis joysticks. Powered by a 110-volt outlet or generator, the control unit with inspection/mapping modules enables the user to create photos and videos. Data such as X and Y gradients, rotation, distance, and water and air pressures are displayed on the monitor.

The 19-inch-long by 6-inch-wide and 5-inch-tall R160 robot has a stainless steel body and four-wheel drivetrain that can navigate 500 feet of pipe.

The robot can be equipped with two types of grinding, milling and cutting equipment. The HA165 and HA195 models can be used with an 8.2 hp (6,000 watt) piston motor or 3.4 hp (2,500 watt) turbine motor driven by high-pressure water.

The portable 77-pound HD70F high-pressure pump generates 2,175 psi at 2.9 gpm. Vehicle-mounted pumps generate 15,000 psi and 29,000 psi. Water pressure and flow settings can be continuously adjusted. The portable cable reel contains 131 feet of hybrid cable and 131 feet of high-pressure hose (29,000 psi maximum). Vehicle-mounted reels contain 500 feet with longer lengths available.

The HA165 has a 3.5-inch vertical stroke for reinstating laterals in 7- to 12-inch pipelines. The HA195 has a 7-inch stroke for use in 8- to 20-inch relined pipes or larger with an axle extender.

The compact WJ160 precision-jet cutting attachment removes tree roots during inspections in 7- to 19-inch pipelines. Fats, oils and grease, sand, sludge, small roots, and other deposits can be jetted away using up to 4,500 psi. Water pressure between 3,000 psi and 15,000 psi eliminates root intrusions by blasting off the main root where it enters the pipe. For larger jobs, the WJ180 ultra-high-pressure attachment delivers up to 29,000 psi for removing calcium and concrete without damaging the wall in 8- to 40-inch lines, including

egg-shaped pipes.

“The system is very accurate,” says Bart van der Zalm, international sales, ID-TEC. “With the WJ160 you have the nozzle next to the camera and high-powered lighting. You can rotate the equipment 500 degrees. You’re able to reach any part of the pipe. Precision-jet cutting is almost like cutting with a laser beam.”

The 3.9-inch-long by 3.9-inch-wide and 4.7-inch-tall CQL160 CCTV inspection module includes a high-definition infinite rotating pan-and-tilt camera and two 1,200-lumen LED lights, all protected by sapphire lenses. 503/504-8474; www.sr-series.com; WWETT 16 booth 1060.