Interested in Inspection?

Get Inspection articles, news and videos right in your inbox! Sign up now.

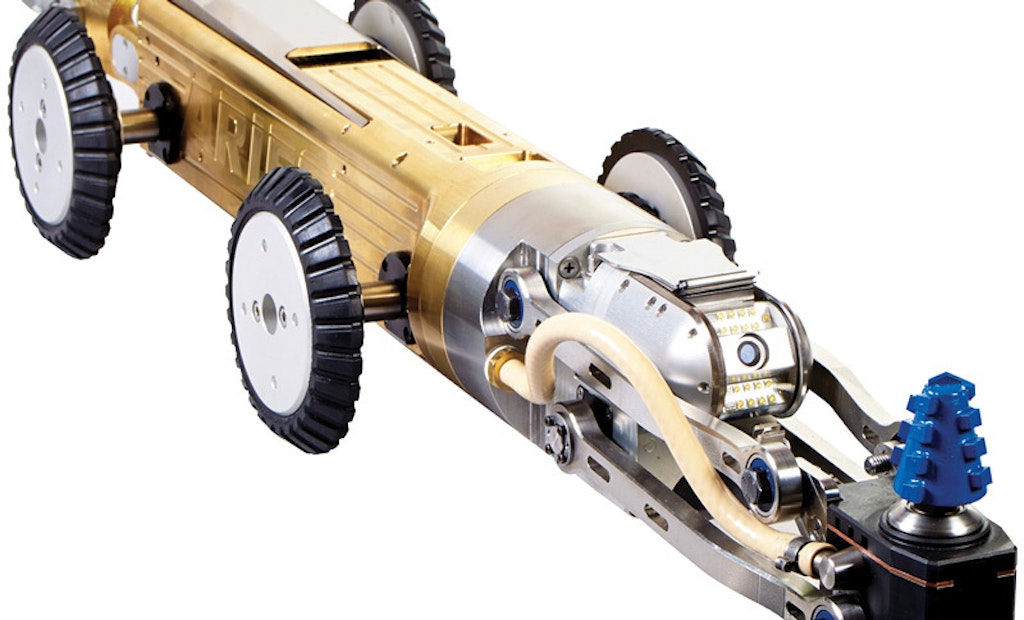

Inspection + Get AlertsThe Wolverine Cutting System pipeline maintenance and inspection robot from Aries Industries is designed to perform pipeline maintenance, visual inspections and reinstate laterals from 6- to 15-inch pipelines. A built-in camera system negates the need to run a secondary camera.

The robot’s stainless steel and brass construction enables contractors to cut or grind a variety of inline obstructions and CIPP materials. The self-propelled, wheeled system travels up to 460 feet and precisely cuts, mills brushes or grinds liners with cutting forces from 1.6 hp (16,000 rpm) to 3.35 hp (12,000 rpm). Cutter and camera functions perform simultaneously and are remote-controlled through a transmitting cable that delivers data to an above-ground workstation.

The cutter was designed by ProKasro of Germany and introduced to the North American market by Aries as an all-inclusive or retrofit system.

“We have the ability to manufacture combination trucks and saw a need in the marketplace for a high-performance, wheeled, remotely driven cutter robot/tractor,” says Nick Kroll, president and CEO of Aries Industries. “In many cases, Aries has built out cutter trucks and left it up to our contractor customers to source a cutter robot. We ultimately decided it made the most sense to provide a fully integrated, turnkey system.”

Demonstrated at the 2013 Pumper & Cleaner Environmental Expo International in Indianapolis, the cutter robot is touring the country as part of Aries’ Cut Across America initiative, offering contractors and municipalities a first-hand look at its capabilities.

“The bottom line is how many more lateral connections can you reinstate in a given hour, a given day or a given week? It really comes down to productivity,” Kroll says.

The all-wheel-drive robot and camera, approximately 24 inches long and 5.5 inches wide, weighs 44 pounds. The tool’s low center of gravity and weight ensure easy navigation in difficult lines. The system has a three-axis rotating cutter head with optional fourth axis for difficult locations.

The grinding and milling head can be easily changed out, Kroll says. “It can cut any pipe that’s been installed. It’s just a matter of getting the appropriate bit in the cutting tool.”

The system has an LED lighted swivel color camera head with optional mainline inspection camera head adapter. The self-cleaning lens features a wiper blade and water jet for a clear view of cutting activities.

A tethered remote enables the operator to drive the robot cutter from the back of the truck or cab. The dual joystick control provides accurate head positioning and remote stabilizing lift for powerful balanced cutting. The tool requires a 165 cfm compressor at 125 psi. Options include behind cab (skid) or PTO-under body mounting as well as a pull-behind trailer. 800/234-7205; www.ariesindustries.com.