Video inspection has advanced the cause of sewer system maintenance and repair: It literally gives contractors a set of eyes under the ground.

But there are times when traditional video images are not enough. For example, in a pipe with a smooth new CIPP liner, it can be hard to spot the exact locations of the sewer laterals that need to be reinstated. And although operators can see the water flowing in a sewer, video provides no real clues to the character or source of that water.

That’s where infrared imaging comes in. These inspection systems enable operators to switch back and forth between traditional video and infrared imaging – and in the latter mode literally see temperature differences. The technology already has a few key applications in wastewater pipe maintenance, and more are likely to emerge as it is deployed more widely in the field.

The first infrared imaging systems displayed in black and white – for example, white as warmer, black as cooler. This technology enables operators to see, for instance, the difference in temperature between the wall of a newly lined pipe and the site of a lateral opening.

More advanced systems show relative temperatures in color and also display the absolute temperature of a precise point within the frame of an image. These can be used for lateral reinstatement after CIPP lining and also for more sophisticated investigations, like sleuthing improper sewer connections.

Embracing the technique

Aries Industries was the first pipeline inspection equipment provider to bring infrared imaging to the wastewater industry. “We saw the technology and asked, ‘How can our industry benefit from it?’” says George Rada, senior product manager.

The first thermal imaging system for pipe inspection, displaying in black-and-white, came on the market in the early 2000s. Its sole application was and remains pinpointing the location of lateral openings behind CIPP pipe lining.

In the lining of smaller-diameter sewers (6 to 10 inches), the lining typically dimples slightly into the laterals, making the locations fairly easy to see with traditional video, Rada says. But when larger pipes are lined, the dimpling may be far less obvious. “In those cases, you can’t rely on observations that the lateral was, say, 32.5 feet from the manhole and in the 2 o’clock position,” Rada says. “You need a positive location.”

Users of the black-and-white thermal imaging system deploy it just after the liner is installed, while it is still warm from curing. At that point, the lateral, having wastewater or ambient-temperature air behind it, is cooler than the rest of the liner, and the difference shows on the thermal imaging display. Operators can navigate to the approximate location of laterals using the video mode, then switch to infrared to pinpoint the lateral site for reinstatement cutting.

Rada notes that the black-and-white technology was adopted mainly by sophisticated, high-volume CIPP lining contractors. Municipalities did not adopt it simply because the vast majority contract for CIPP lining rather than do it in-house.

Living color

The next step in evolution of thermal imaging for pipe inspection made its debut in 2010: It can display infrared images in black-and-white or in color. The camera is about 14 inches long and has a cylindrical rear body. Two arms at the front hold a cube-shaped pan-and-tilt camera and light head.

The camera head has visible-light and infrared lenses on opposite ends. Using a remote control panel, the operator can switch from one mode to the other. A pan function lets the operator pan continuously 360 degrees left to right. The head also rotates clockwise or counterclockwise in either viewing mode.

Because of the extra space needed in the camera head for the infrared optics, there is no room for zoom components for the visible-light camera. The infrared lens has digital zoom to 2x and 4x.

While the visible-light lens is surrounded by 12 warm-white LEDs, the infrared camera needs no lighting. In the visible-light mode, the control panel displays a distance readout. In the infrared mode, the monitor display includes three additional features:

• A blue dot in the center that pinpoints the temperature target.

• A digital readout that displays the temperature of the blue dot’s target – the reading is accurate to ± 0.5 a degree.

• A bar icon that displays temperature on a vertical scale from 0 to 300 degrees F. Readings can be switched to Celsius or turned off.

In the black-and-white infrared mode, the camera can show the highest temperature as dark and the lowest as white, or the reverse. In the color mode, the system can show temperature variations in regular color or in more intense color. These color differences show relative – not absolute – temperatures.

The system is designed to be controlled by standard camera controller equipment, helping to keep total inspection system cost affordable. A few switches on the control panel are repurposed to accommodate the infrared viewing.

Applications emerging

The most obvious application for the technology is pinpointing sewer lateral locations in lined pipe – but with greater accuracy. “The operator can adjust the color intensity of the display to better show temperature differences,” says Rada. “If the colors are still hard to read, the operator can focus the blue dot on the target area and read the absolute temperature.”

The added temperature measurement precision has opened more applications for infrared imaging in underground piping. One promising application is in restoring water service connections after fabric lining of water mains.

Before lining, services are typically closed with plastic plugs. After lining, these plugs appear as small protrusions in the liner. But in thicker water pipe materials, such as asbestos cement, some plugs may be forced entirely into the pipe wall so that they do not leave any visible markers in the liner. Here again, temperature differences that appear on the infrared display enable technicians to locate the service connections precisely.

A potentially more powerful application emerged in early 2010 when the technology was used by an engineering firm charged with helping an eastern city identify improper discharges of sanitary wastewater into storm sewers.

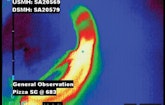

Here, the high precision of the full-color thermal imaging can identify locations where warmer sanitary sewer flows meet colder ground-temperature stormwater flows. In one instance, the engineers easily detected a hot-water discharge from a pizza parlor entering a storm sewer.

Looking ahead

Rada believes more applications for the color infrared imaging technology will emerge as engineers, contractors and municipalities put it to work. “I am sure we don’t know all the potential uses yet,” he says. “We’re always looking for new ways to solve problems in underground infrastructure. Undoubtedly, more applications will come up.”